Case Studies

Case Examples

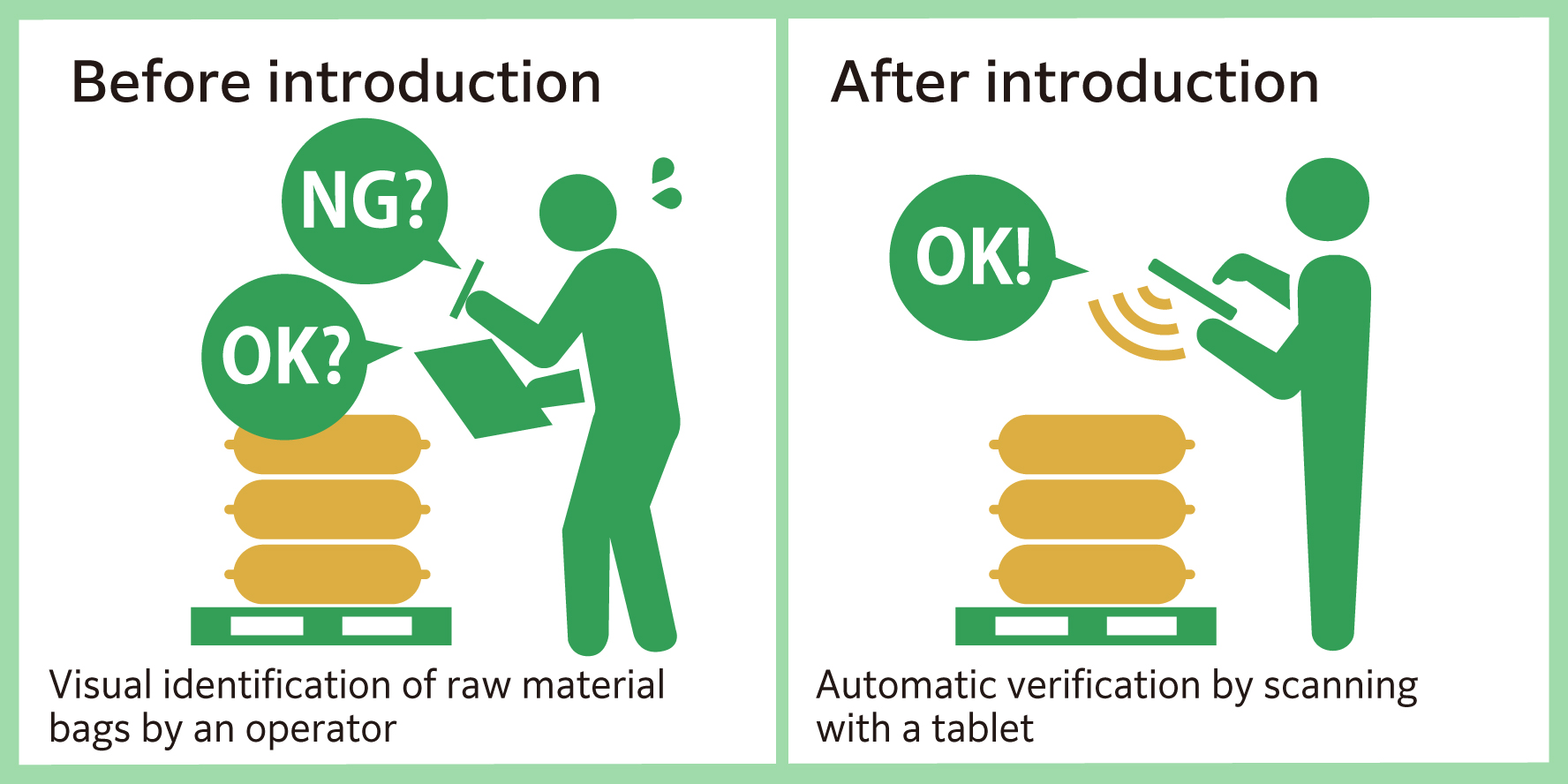

Using a tablet to prevent incorrect raw material charging

Material Receiving and Powder Feeding Process

Type of Industry

Bread making company

Introduced Products

PV Checker Mobile

Customer requests

We want to make the most of tablets in the factory!

A customer has decided to introduce tablets as a step toward IoT implementation on the production site. While comprehensively considering “what can be done,” such as visualizing production status and sharing work schedules, the customer asked us, “When raw materials are charged into equipment, whether the material is correct is left to the operator’s judgment. Could a tablet be used to reliably prevent incorrect charging?”

Suggestions from TSUKASA

Prevention of incorrect charging using the “PV Checker Mobile”

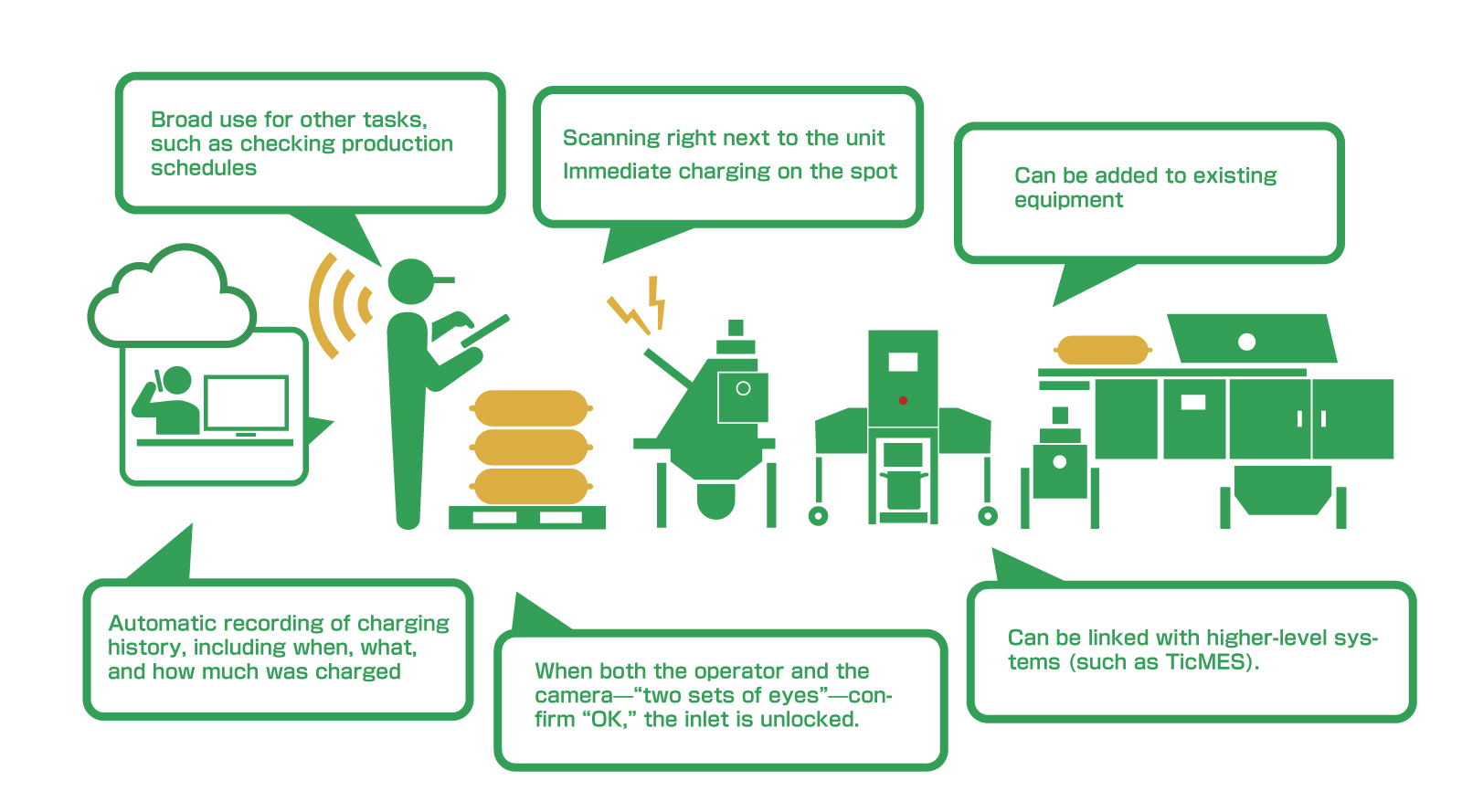

Using the tablet, the operator scans the raw material bags transported on a cart. We proposed the “PV Checker Mobile,” which the operator uses to have it recognize surface designs (text, patterns, colors, etc.) and unlock the inlet only when the material is verified as “OK.” Incorrect charging can be completely prevented through double checking in combination with visual inspection by the operator.

One tablet can handle multiple raw materials.

Multiple bag surface designs can be registered on one tablet. By registering items in advance, such as “Company A’s wheat flour,” “Company B’s wheat flour,” and “Company C’s sugar,” the operator can move around the factory while checking raw materials, enabling maximum utilization of the tablet’s mobility. Of course, the same tablet can also be used for other tasks.

The operator can perform checks right next to the unit before charging.

Since the operator can check raw materials while moving around, there is no need to transport raw materials to the camera location using a cart or conveyor. The operator can check the material right next to the unit and charge it immediately without the extra step of moving heavy bags.

Improved traceability of charging records

Because the system automatically records when, which raw material, and how much was charged, there is no need for memo notes or stickers, improving traceability.

Combination device (example)

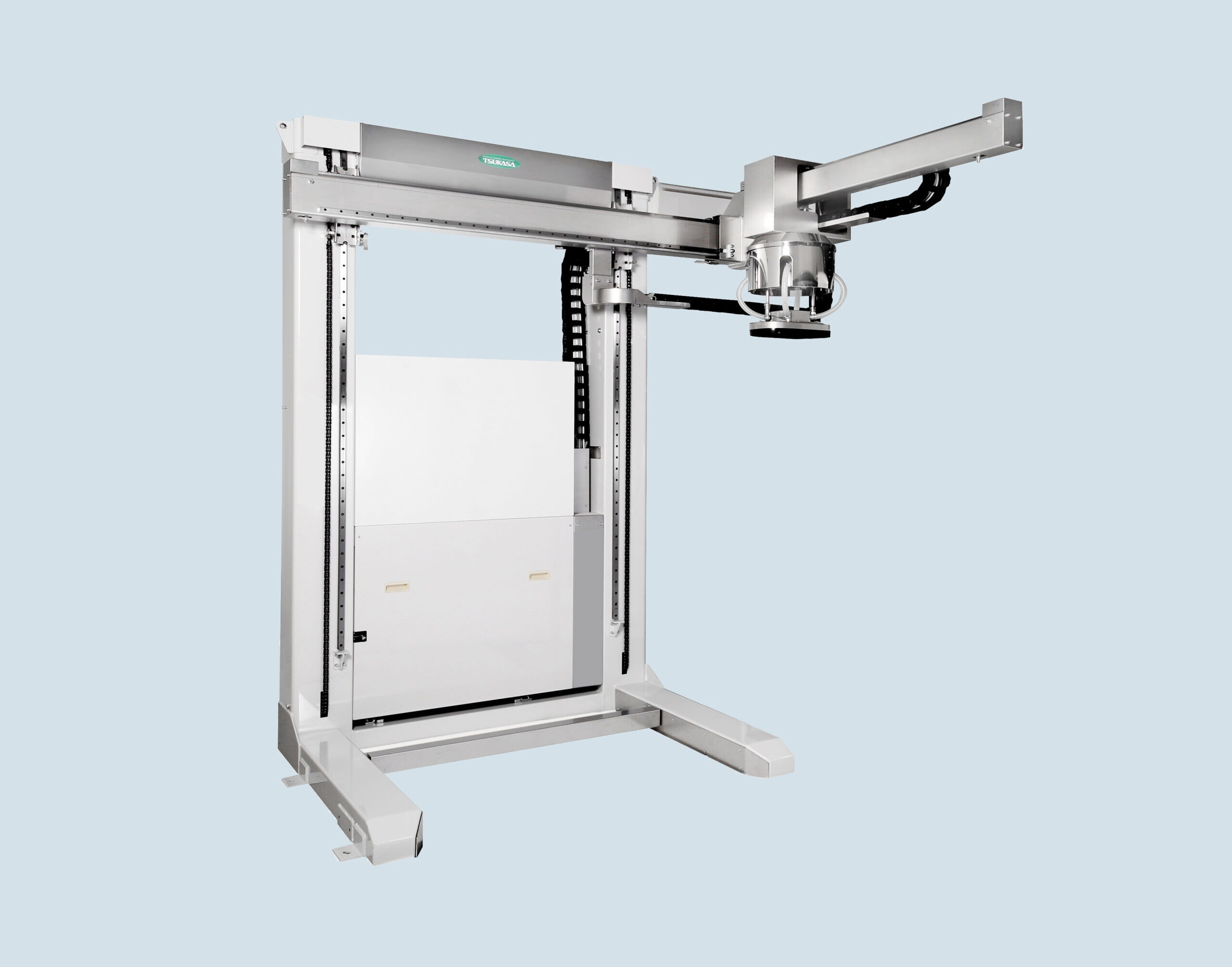

Automatic bag opening System

By combining it with the “Depalletizer Robo (DPL),” which feeds powder bags to an automatic bag-opening system, the operator can reliably check the types of bags on the pallet.

▲Depalletizer robo

Raw material feeding equipment

Even when the operator opens a bag manually to charge raw materials, human error can be reliably prevented. Automatic switching of the transport line to downstream processes is also possible.

▲Dumping Server and LINESIFTER Integrated Model

Automatic dividing and weighing equipment

Safe and reliable weighing and blending of multiple raw materials! The raw material stocker is unlocked only when the image verification result is “OK,” preventing accidental human error.

▲Divider Scale Terminal

Message from TSUKASA

Equipped with our in-house developed app, enabling flexible customization

The app installed on “PV Checker Mobile” has original specifications developed by TSUKASA. We can also flexibly accommodate customization requests, such as “using it in conjunction with a higher-level system.”