Case Studies

Case Examples

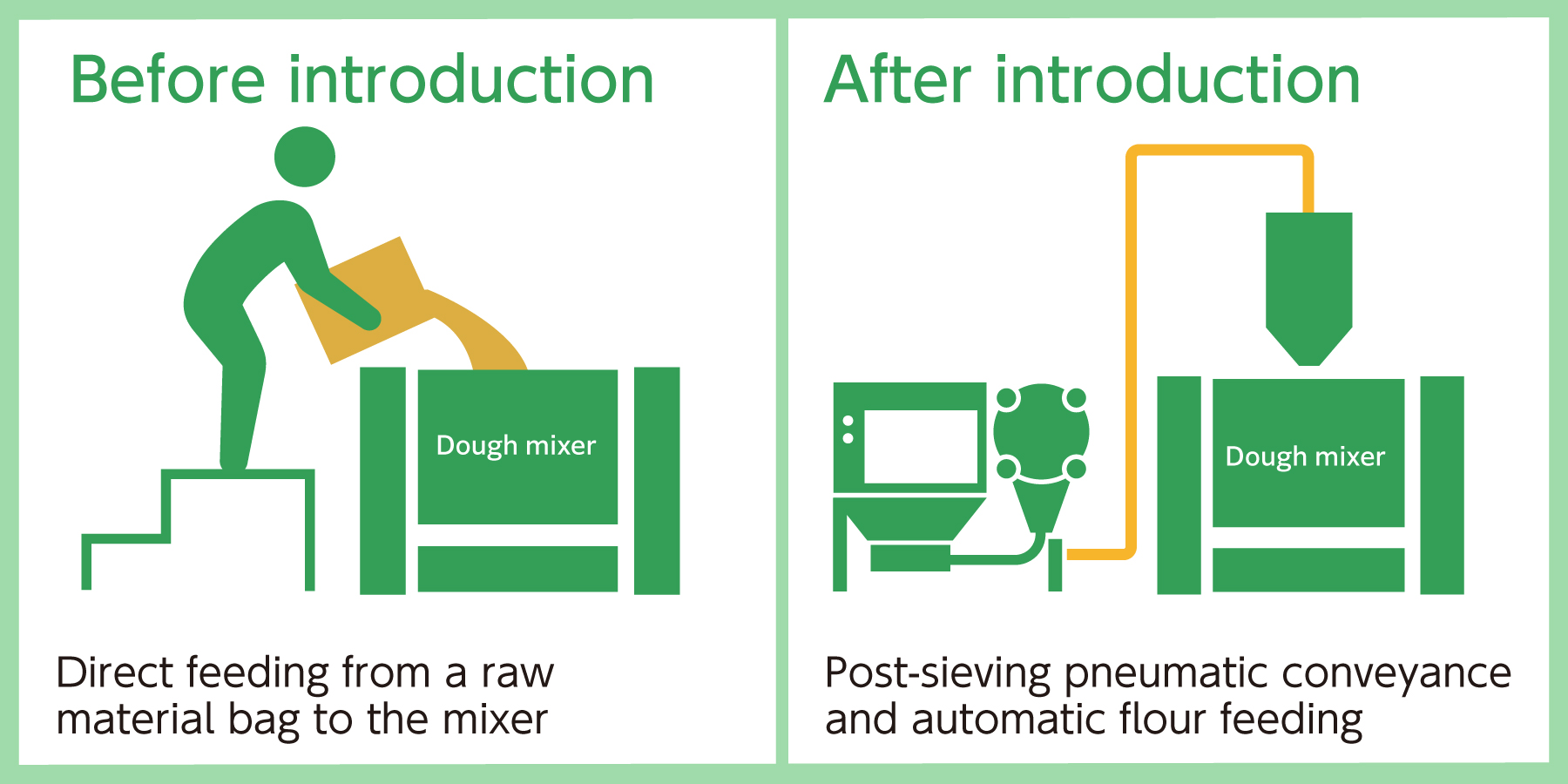

Upon receipt, flour is immediately sieved and pneumatically conveyed to the mixer.

Material Receiving and Powder Feeding Process

Type of Industry

Bread making company

Introduced Products

Dumping Server and LINESIFTER® Integrated Type Pressure Feed Hopper

Customer requests

Elimination of the burden of manual feeding + Sieving before feeding to the mixer

A customer who manually feeds raw materials into a bread mixer contacted us with a request to "eliminate the heavy work of lifting and carrying bags." We also received customer feedback saying, "Due to trends in the bread-making industry, raw materials are supposed to be sieved before being fed into the mixer for foreign object prevention. But there is no space to install a sieving machine in our current factory."

Suggestions from TSUKASA

Pneumatic conveyance line for automatic powder feeding to the mixer

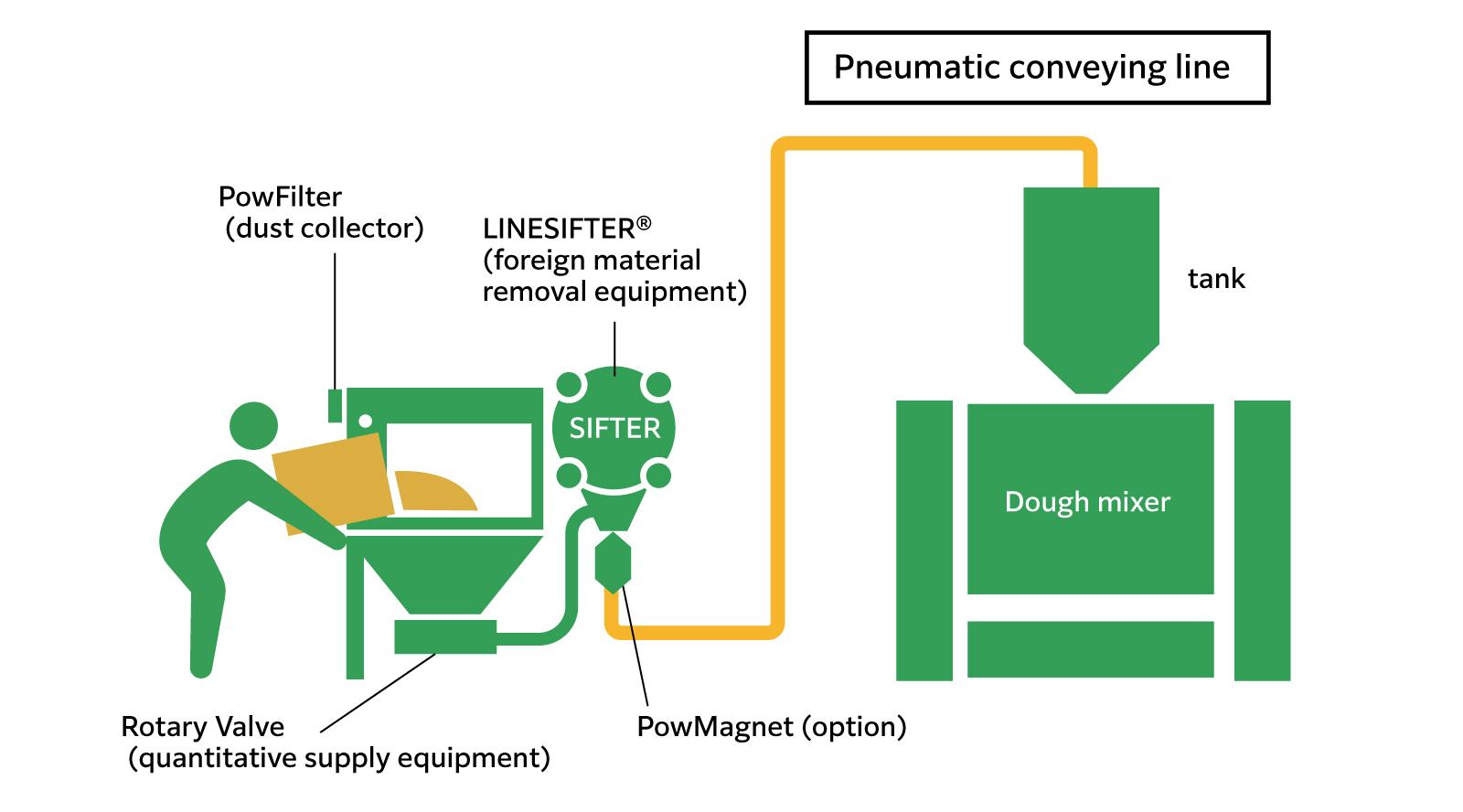

We proposed a system where bagged raw materials received at the factory are manually put into the "Dumping Server," which is connected via a pneumatic conveyance line to the mixer, enabling automatic powder feeding without burden on the operator.

Hybrid machine for receiving and sieving raw materials

We offered the "Dumping Server and LINESIFTER® Integrated Type Pressure Feed Hopper," which combines the following functions into a single unit: receiving powdered raw materials, sieving, breaking up lumps, removing foreign materials, and collecting dust. We have taken care to ensure that raw materials are put into the mixer in a "clean and homogeneous state" without the risk of contamination by foreign matter.

Dumping Server and LINESIFTER® Integrated Type Pressure Feed Hopper

Results of introduction

Elimination of heavy manual labor

All the operator needs to do is load the raw materials into the Dumping Server; the entire process up to loading into the mixer is automated. The low-height inlet design makes feeding raw materials easy.

Installation at a location separate from the mixer is also possible.

Since the raw materials are transported via a pneumatic conveyance line, there is no need to place the Dumping Server near the mixer. This customer installed the system in an empty space in their raw materials warehouse, thus eliminating the need to roll a cart to transport raw materials into the factory.

Effective use of limited factory space

The customer initially considered separately installing a vibrational sieve machine, but opted for the "Dumping Server and LINESIFTER® Integrated Type Pressure Feed Hopper," which integrates the functions of raw material reception, sieving, breaking up lumps, removing foreign materials, and collecting dust into a single unit. Its compact size allowed easy installation even in the existing factory with limited space.

Breaking up lumps improves the quality of bread

Because powder-form raw materials are sieved and lumps are broken up before being added to the mixer, air easily enters between the powders, improving water absorption during dough kneading. We received the following feedback from the customer: "Because the powder is uniform, the quality is stable, and we can now make fluffy, chewy bread."