Case Studies

Case Examples

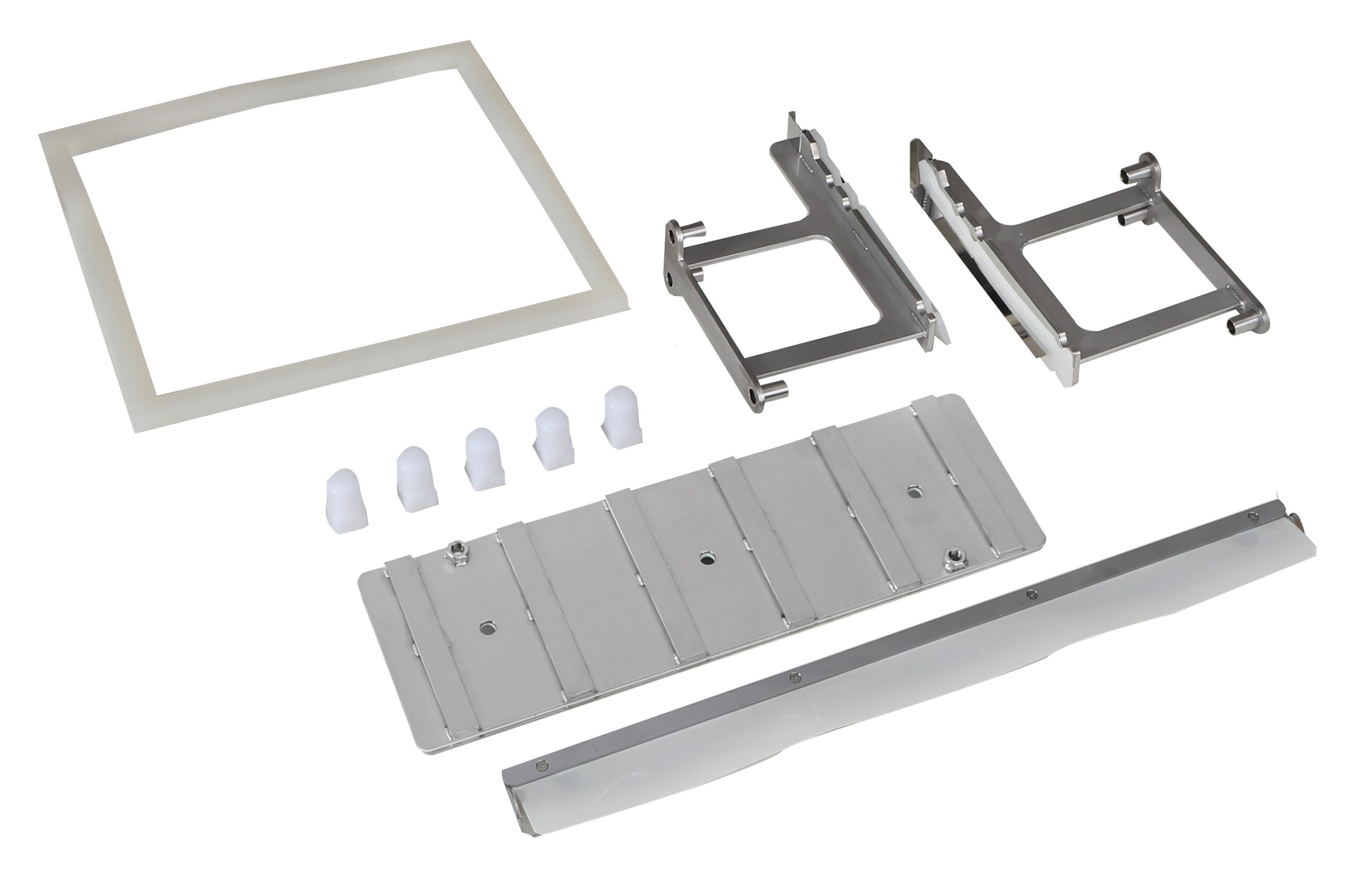

Promotion of tool-less disassembly and water-washing of automatic bag-opening equipment

Material Receiving and Powder Feeding Process

Type of Industry

Beverage/food manufacturer

Introduced Products

PowOpener Disassembly washing type

Background and problem

Tools are required to remove parts to be washed

Water-washing of conventional PowOpener (automatic bag-opening equipment) required tools to remove the bolts and remove each part. In addition, air guns were used to clean the inside of the equipment, not water. Therefore, a customer who handles powder that requires strict hygiene asked us to make some equipment so that anyone could easily remove the parts, and said they want to wash off the residue inside the equipment with water.

* Tools are required for some parts.

* Tools are required for some parts.

Suggestions from TSUKASA

Reviewing the equipment structure and promoting tool-less disassembly

⚫︎Toward the realization of "tool-less"

We reviewed the overall structure and materials of the PowOpener. A knob bolt was adopted to make it easy to disassemble the equipment, remove parts, and restore the equipment after washing everything manually.

⚫︎Ensuring safety

Since people's hands are more likely to come in contact with the device, we strengthened safety mechanisms to prevent the device from operating unexpectedly after the power is turned off due to residual air pressure, etc.

⚫︎Improved the cleaning function inside the equipment

In addition to enhancing the function of "dry cleaning" by air guns and other means, we also made it so the equipment could be washed with water.

We reviewed the overall structure and materials of the PowOpener. A knob bolt was adopted to make it easy to disassemble the equipment, remove parts, and restore the equipment after washing everything manually.

⚫︎Ensuring safety

Since people's hands are more likely to come in contact with the device, we strengthened safety mechanisms to prevent the device from operating unexpectedly after the power is turned off due to residual air pressure, etc.

⚫︎Improved the cleaning function inside the equipment

In addition to enhancing the function of "dry cleaning" by air guns and other means, we also made it so the equipment could be washed with water.

Results of introduction

⚫︎Smooth washing schedule

By promoting tool-less use, anyone can disassemble and restore equipment manually, so that washing schedules proceed as planned in line with the hygiene management requirements of customer production lines.

Example 1

Disassembling the equipment daily and washing it with water

Example 2

Making a week-schedule for equipment cleaning

Weekdays: Blowing and vacuum cleaning with an air gun

Weekends: Disassembly for water-washing (dry the equipment until Monday morning)

⚫︎Easier cleaning for parts that were difficult to clean

The overall structure has been revised to ensure that the areas that were difficult to clean, such as because people's hands could not fit in there easily or because air did not reach, are now easily accessible.

⚫︎Measures against contamination and allergens

If the equipment is disassembled and washed thoroughly with water, there will be no powder residue left inside. This is effective in preventing contamination and removing allergens after restarting operation.

By promoting tool-less use, anyone can disassemble and restore equipment manually, so that washing schedules proceed as planned in line with the hygiene management requirements of customer production lines.

Example 1

Disassembling the equipment daily and washing it with water

Example 2

Making a week-schedule for equipment cleaning

Weekdays: Blowing and vacuum cleaning with an air gun

Weekends: Disassembly for water-washing (dry the equipment until Monday morning)

⚫︎Easier cleaning for parts that were difficult to clean

The overall structure has been revised to ensure that the areas that were difficult to clean, such as because people's hands could not fit in there easily or because air did not reach, are now easily accessible.

⚫︎Measures against contamination and allergens

If the equipment is disassembled and washed thoroughly with water, there will be no powder residue left inside. This is effective in preventing contamination and removing allergens after restarting operation.