Case Studies

Case Examples

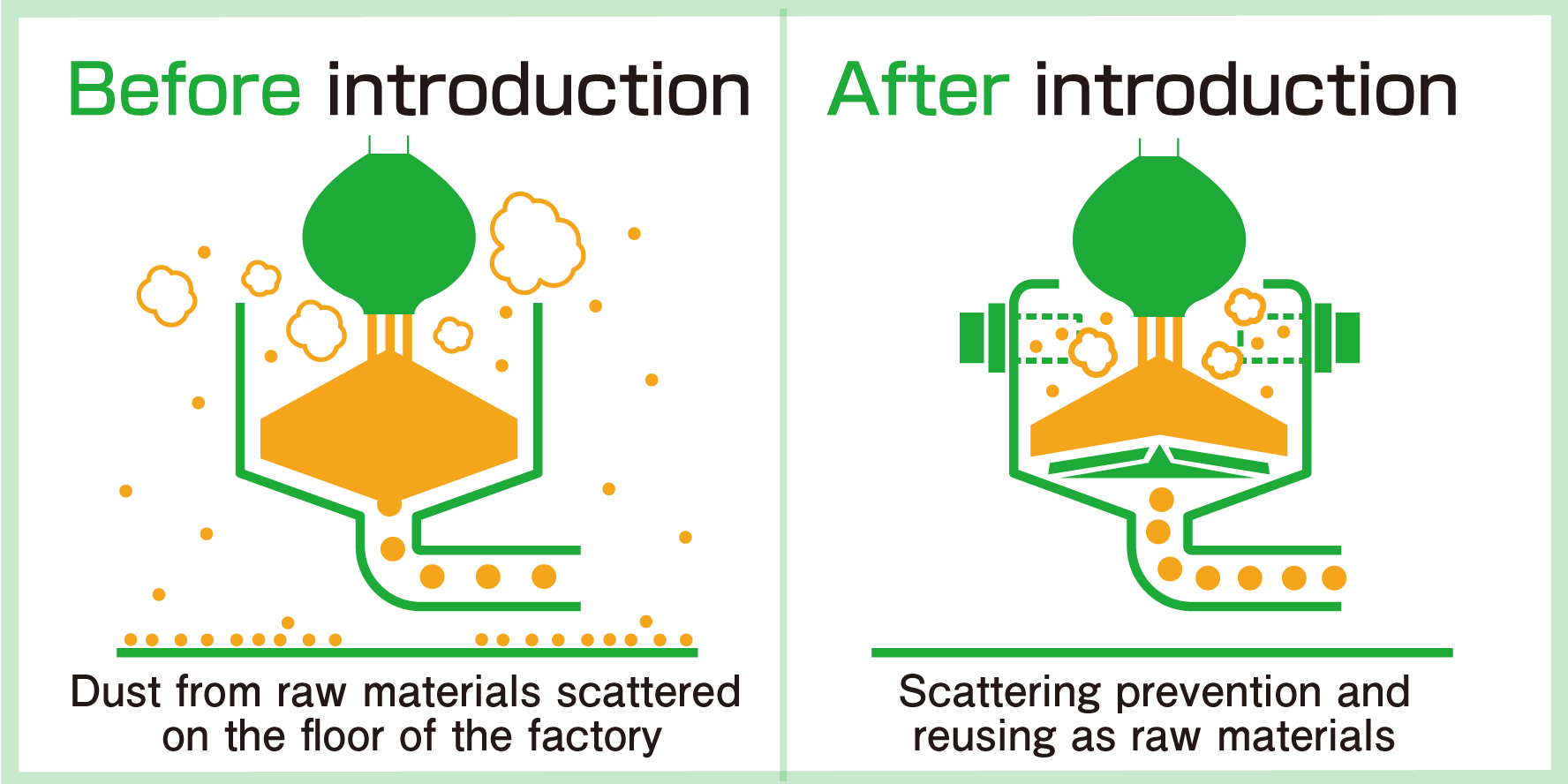

Integrated Opening and Dust Collection to Reduce Calcium Carbonate Loss

Material Receiving and Powder Feeding Process

Type of Industry

Metal manufacturer (welding rod production line)

Introduced Products

FleconOpener

Background and problem

We would like to improve the working environment by preventing the scattering of calcium carbonate

In a production line for welding rods, the floor had become a "world of silver" because dust was scattering when calcium carbonate (coating) was put into tanks.

There were issues such as having to vacuum every time the floor turned white, along with problems related to the work environment, such as the contamination of work clothes. This customer consulted with us, asking "Is it possible to put calcium carbonate powders into tanks without scattering occurring?"

There were issues such as having to vacuum every time the floor turned white, along with problems related to the work environment, such as the contamination of work clothes. This customer consulted with us, asking "Is it possible to put calcium carbonate powders into tanks without scattering occurring?"

Suggestions from Tsukasa

Providing added value by introducing a FleconOpener

We recommended introducing a FleconOpener to prevent dust from scattering outside the machine, which has a built-in dust collector. We successfully won over the customer by highlighting that TSUKASA's equipment brings various added value. This includes not only scattering prevention, but also providing improvements to the working environment, reducing the loss of raw materials, and furthermore, ensuring the safety of the workplace.

Why TSUKASA was chosen

Reuse of "waste and disposal materials" by incorporating a dust collection function into a bag opening machine

In separately-installed spot dust collectors, adsorbed calcium carbonate turns into waste. TSUKASA's FleconOpener has a built-in dust collector that can be integrated into equipment to reduce powder loss by returning collected powders into the equipment. This technology is unique to TSUKASA for both bag opening machines and dust collectors which are handled as a single unit by TSUKASA.

Results of introduction

Prevention of dust scattering

Scattering of calcium carbonate dust was controlled. We were able to contribute to building a work environment where focusing on work was possible without the need for time-consuming periodic "vacuuming."

Reduced loss of raw materials

Disposal powders that are to be disposed of where the separately-installed spot collectors are used can be reused as raw materials for products. In addition, this has resulted in multifaceted cost-saving measures such as a reduction in disposal costs.

Creation of a healthy work environment

We were able to help realize a healthy and comfortable work environment by eliminating dust scattering and preventing operators from “inhaling” dust.

More effects

Also ensuring safety when opening bags

Depending on the customer's business conditions, operators may be at risk of accidental drops when hoisting a FleconOpener Stock to open a bag. TSUKASA's FleconOpener makes it safer when opening bags because it has a “ring for the bag receptacle.”