Case Studies

Useful Worksite Knowledge

【New Product】 Automation tailored to bag-opening volume in the factory

An operator lifts raw material bags and opens them manually. We want to automate this heavy task, but the processing volume at the factory is not very large. TSUKASA presents a new product for 2025 designed specifically for such customers.

What bag-opening volume per hour?

Up to 200 bags/hour

↓

Fully automatic bag opening with multiple functions

"Automatic bag opening System"

Fully automatic bag opening with multiple functions

"Automatic bag opening System"

NEW!

50 to 60 bags/h

↓

A semi-automatic bag opening unit

"PowOpener Assist / PowBalancer"

A semi-automatic bag opening unit

"PowOpener Assist / PowBalancer"

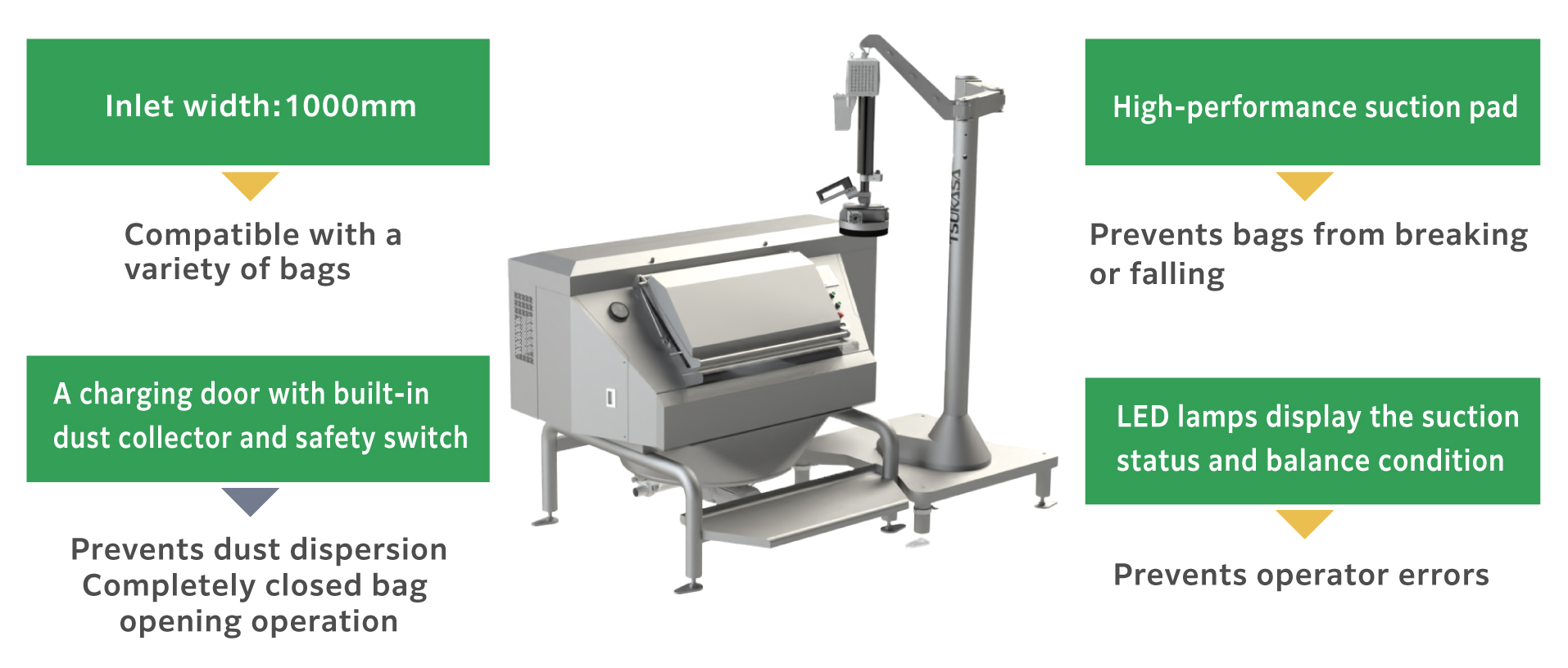

Compact automatic bag opener equipped with a hand balancer

"PowOpener Assist / PowBalancer"

1. Place the suction pad against the raw material bag

2. When it is lightly lifted, the assist function turns ON

Support it with your hands and guide it to the inlet

3. Open the door and set the raw material bag

Touch the start button

4. Automatic bag opening and raw material discharge

5. Collect the empty bag

2. When it is lightly lifted, the assist function turns ON

Support it with your hands and guide it to the inlet

3. Open the door and set the raw material bag

Touch the start button

4. Automatic bag opening and raw material discharge

5. Collect the empty bag

Various usage options depending on the factory situation

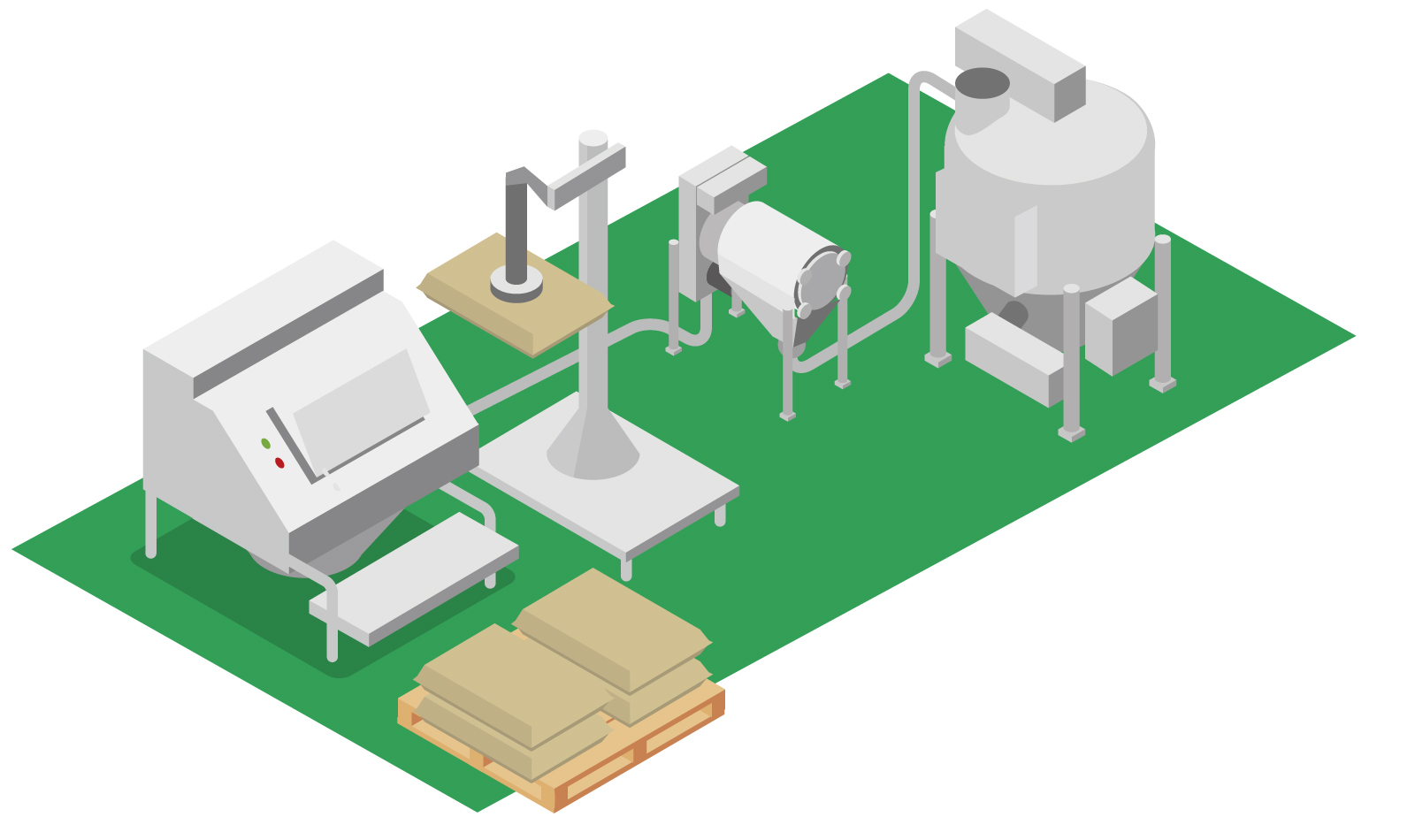

Pneumatic conveyance of the opened raw material to the downstream process

The discharged raw material can be pneumatically conveyed, sieved by a LINESIFTER, and then sent to the downstream process such as mixing.

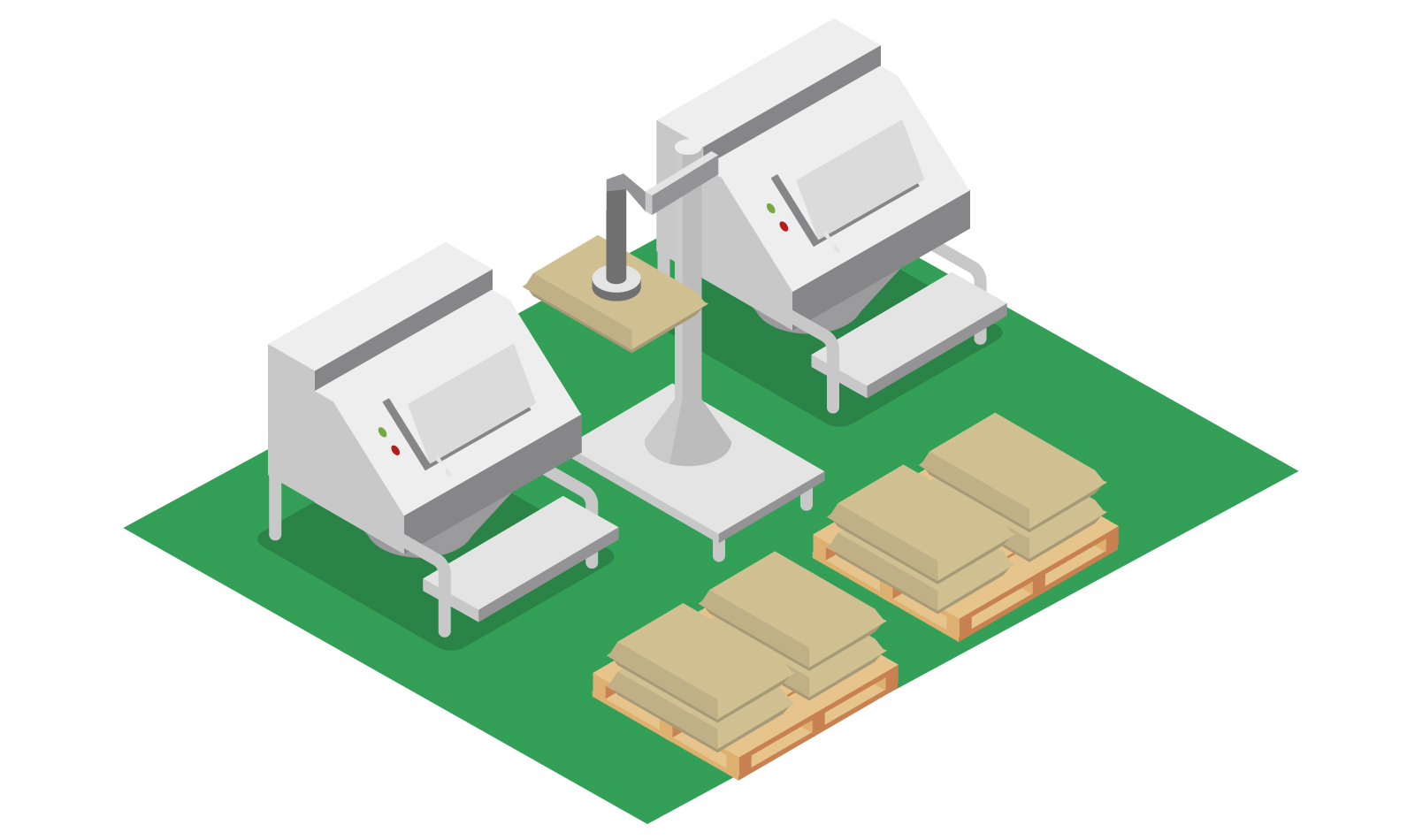

Combined use of two PowOpener Assists is also possible

It is also possible to sort bags—for example, “sending flour bags to the right and granulated sugar bags to the left”—and pneumatically convey each to its respective downstream process.

PowOpener Assist / PowBalancer