Case Studies

Useful Worksite Knowledge

Reduce Your Workload With Automation[Lifting Heavy Powder Bags]

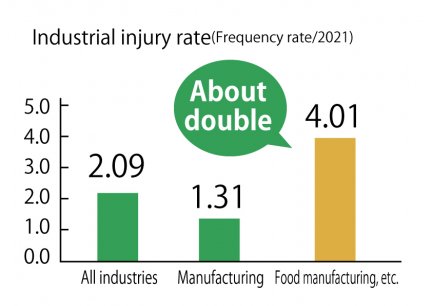

It is hard work to lift a bag containing powder by hand, open the contents, and feed it into a processing machine. In the manufacturing industry, the incidence rate of industrial accidents is higher than in all other industries, and in food manufacturers, the rate is even higher.

Lower back pain accounts for nearly 60% of all occupational illnesses

Among food manufacturers, nearly 60% of all occupational illnesses that require four or more days off from work are caused by lower back pain.

For men, 40% of their body weight, and for women, 60% of the weight limit for men

Heavy items should be handled under 40% of the body weight for men. For women, under 60% of the weight limit for men.

For men weighing 60 kg, 60 kg x 40% = up to 24 kg

For women weighing 50 kg, 50 kg x 40% x 60% = up to 12 kg

For men weighing 60 kg, 60 kg x 40% = up to 24 kg

For women weighing 50 kg, 50 kg x 40% x 60% = up to 12 kg

Automation of production lines is attracting attention for preventing overburden on workers.

Automatic bag opening System

Powder bags can be supplied, opened, and foreign matter can be removed all with one unit.

Depalletizer robo

Automatic supply of powder bags from pallets to bag-opening equipment

PowOpener

The bag can be opened and the contents can be discharged automatically

Depalletizer robo

Automatic supply of powder bags from pallets to bag-opening equipment

PowOpener

The bag can be opened and the contents can be discharged automatically

TSUKASA considers there are three points of success in automation

⚫︎Understanding the benefits of automation

When considering automation, it is important to understand specifically what advantages and disadvantages your company has, such as “improving retention rate and securing human resources,” “improving production efficiency at plants,” and “cost effects over the medium to long term.”

⚫︎Consensus building on site

It is natural that there is a sense of resistance to changing the process that you are used to. Hold an in-house briefing session and build awareness regarding "what is the purpose of automation?" with everyone.

⚫︎The ability to execute plans, which includes administration

Instead of having the attitude of "let's automate things because there are no people", take on the stance of "let’s improve the worksite environment with automation!" If you work with a positive attitude, you will be able to see the next improvement measures from there.

Please feel free to contact Tsukasa Kogyo for a consultation on current problems your facing and for the introduction flow of automation!

When considering automation, it is important to understand specifically what advantages and disadvantages your company has, such as “improving retention rate and securing human resources,” “improving production efficiency at plants,” and “cost effects over the medium to long term.”

⚫︎Consensus building on site

It is natural that there is a sense of resistance to changing the process that you are used to. Hold an in-house briefing session and build awareness regarding "what is the purpose of automation?" with everyone.

⚫︎The ability to execute plans, which includes administration

Instead of having the attitude of "let's automate things because there are no people", take on the stance of "let’s improve the worksite environment with automation!" If you work with a positive attitude, you will be able to see the next improvement measures from there.

Please feel free to contact Tsukasa Kogyo for a consultation on current problems your facing and for the introduction flow of automation!