Case Studies

Useful Worksite Knowledge

Digital Technology Supporting the Five Senses

The use of digital technology will be a major force in addressing the labor shortages in the manufacturing industry. In order to achieve "automation of simple tasks" and "creation of data (visualization) for parts that people make decisions on", we will introduce TSUKASA’s direction regarding what it can do.

Is your plant line in the following state right now?

⚫︎We judge line and product abnormalities with the five senses of a person

⚫︎Production is hampered when skilled technicians are not present

⚫︎More than 90% of the manufacturing industry is suffering from a labor shortage!

There are no young people who can inherit the skills of craftsmen

⚫︎Work requires manual labor, and it is physically demanding

⚫︎I am worried about human error occurring such as people overlooking things

⚫︎It is common practice for people to learn skills by watching

The shortage of engineers is a challenge for the manufacturing industry as a whole, and a smooth transfer of skills cannot be expected immediately. Therefore, by promoting automation and the use of IT for powder equipment, TSUKASA is proposing the fusion of craftsmen’s skills and the latest digital technology.

⚫︎Production is hampered when skilled technicians are not present

⚫︎More than 90% of the manufacturing industry is suffering from a labor shortage!

There are no young people who can inherit the skills of craftsmen

⚫︎Work requires manual labor, and it is physically demanding

⚫︎I am worried about human error occurring such as people overlooking things

⚫︎It is common practice for people to learn skills by watching

The shortage of engineers is a challenge for the manufacturing industry as a whole, and a smooth transfer of skills cannot be expected immediately. Therefore, by promoting automation and the use of IT for powder equipment, TSUKASA is proposing the fusion of craftsmen’s skills and the latest digital technology.

Four directions of TSUKASA

To customers who are thinking: “How do we actually go about digitalization?”

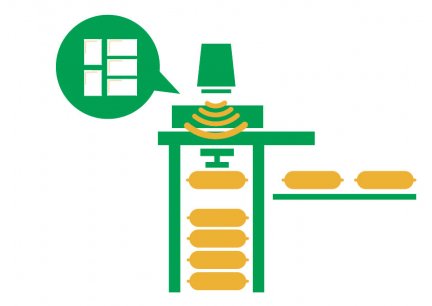

For example, if supplying powder bags from a Depalletizer robo to PowOpener with an automatic bag opening system

Summary

In order to achieve a balance between "proactively automating simple tasks" and "digitizing (visualizing) parts that rely on the human senses", TSUKASA will work together with you to grasp your current work situation and consider what we can do to improve efficiency. For those who are thinking "I'm interested in promoting digitalization, but how do we actually proceed?": Please do not hesitate to contact us.

Harnessing artificial intelligence

After

AI automatically recognizes patterns from image data

Each time the AI learns from data, the accuracy increases

AI automatically recognizes patterns from image data

Each time the AI learns from data, the accuracy increases

Before

A person judges the pattern of the powder bag on the pallet and sets it on the touch panel

A person judges the pattern of the powder bag on the pallet and sets it on the touch panel

DX (Digital Transformation)

Before

Handling abnormalities during operation through corrective maintenance and preventive maintenance

Handling abnormalities during operation through corrective maintenance and preventive maintenance

After

Predictive maintenance by visualizing the operation status through PowMaintenance remote monitoring

Predictive maintenance by visualizing the operation status through PowMaintenance remote monitoring

Using robot technology

Before

Heavy manual lifting of powder bags to a belt conveyor

Heavy manual lifting of powder bags to a belt conveyor

After

When the pallet is set, a robot arm automatically supplies powder bags

When the pallet is set, a robot arm automatically supplies powder bags

Human resource development support

Before

Based on on-the-job training, and the transfer of skills has been a long-standing challenge

Based on on-the-job training, and the transfer of skills has been a long-standing challenge

After

Engineers from TSUKASA visit plants to hold seminars

Online seminars are also held

Engineers from TSUKASA visit plants to hold seminars

Online seminars are also held