Case Studies

Useful Worksite Knowledge

Line structure theory (receiving and feeding of raw materials)

For customers who are interested in line automation and efficiency, but want to know what kind of work is best for their factory size and work style, or are unable to choose from a variety of models, here is an example of how to consider the line configuration in the raw material receiving and supplying process.

The customer factory

● They handle a large amount of raw materials every day

● There are not so many types of raw materials

↓

What we would like to be considered is:

● There are not so many types of raw materials

↓

What we would like to be considered is:

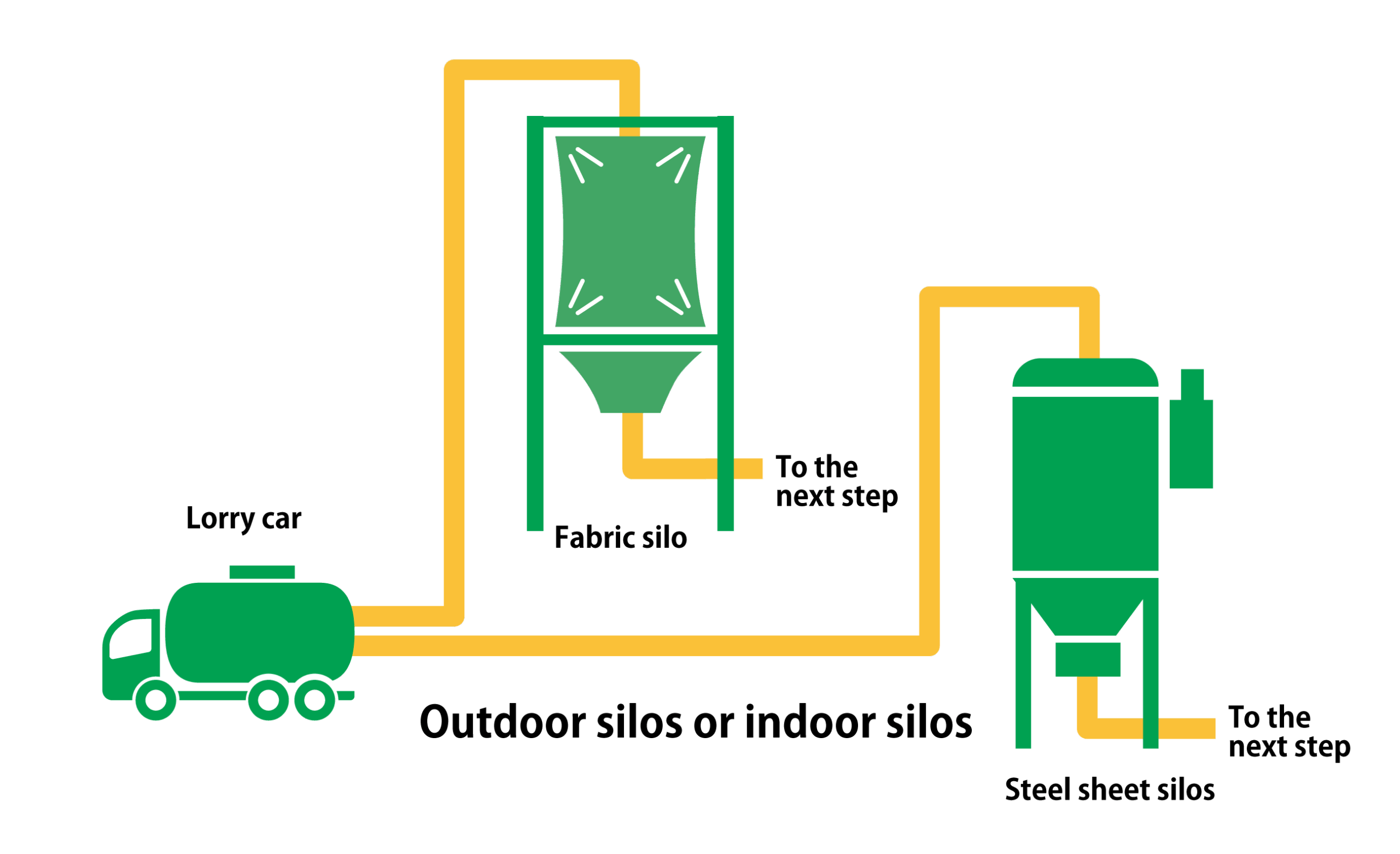

Acceptance in silos from lorry cars

There are two patterns for weighing stock raw materials

We have a lineup of steel sheet silos for outdoor and indoor use, as well as fabric silos for indoor use.

One pattern is that raw materials stocked in a silo can be weighed under the silo and then transported, while the other pattern is that raw materials shipped from the silo can be received and weighed later (silo height can be reduced).

One pattern is that raw materials stocked in a silo can be weighed under the silo and then transported, while the other pattern is that raw materials shipped from the silo can be received and weighed later (silo height can be reduced).

The customer factory

● Raw materials are delivered in paper bags

● There are many kinds of raw materials

↓

What we would like be to considered is:

● There are many kinds of raw materials

↓

What we would like be to considered is:

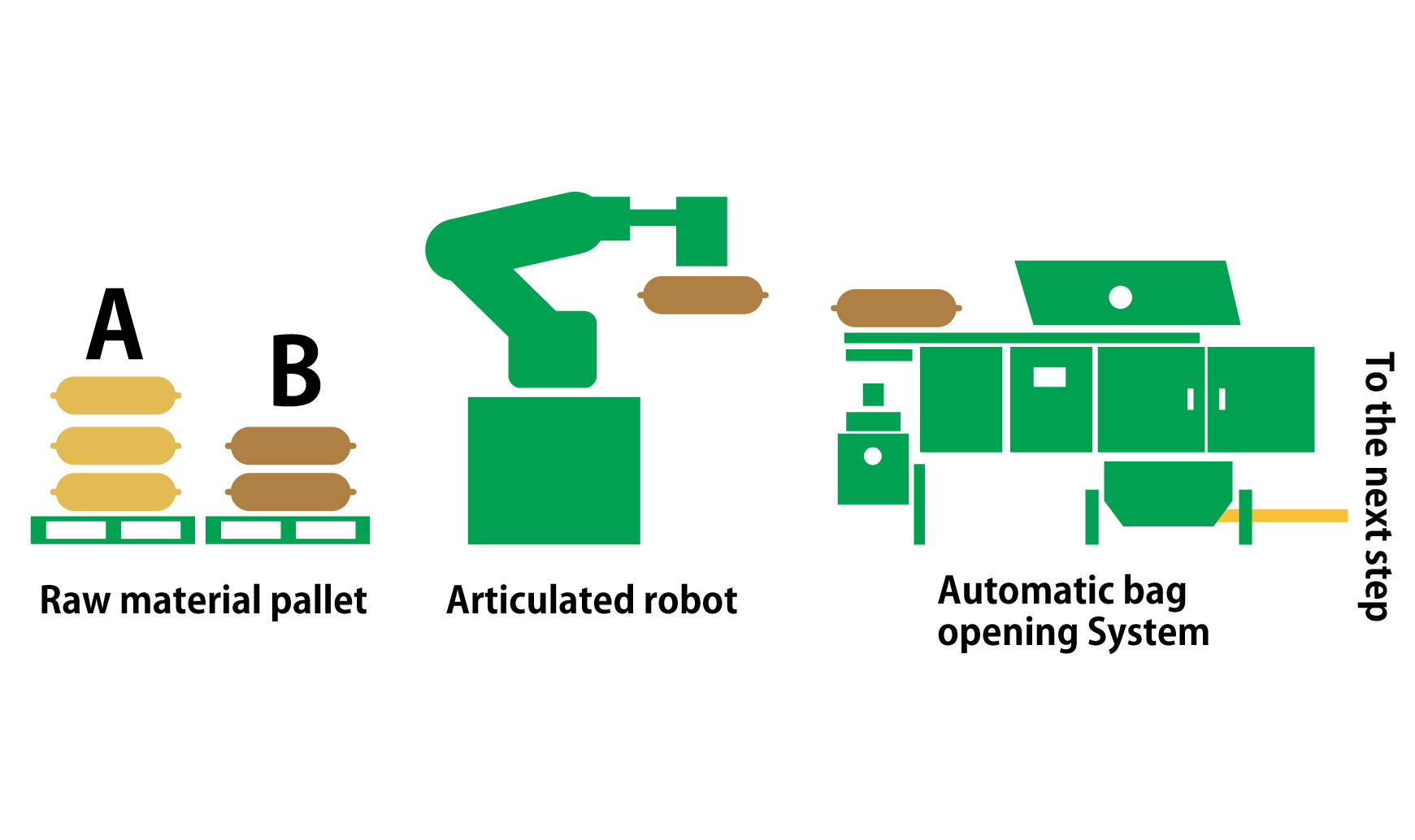

The use of the Automatic bag opening System

Only the amount of raw materials to be used can be opened

The bag can be opened only for the raw materials you want to use, such as one batch, so there is no need to install a large-scale silo. Moreover, even if there are multiple types of raw materials, when using the articulated robot specifications, the required number of bags can be supplied from multiple raw material pallets to the Automatic bag opening System (raw material A × 3 bags, raw material B × 2 bags, etc.).

* In addition to this, we can handle a variety of other forms such as receiving from AMR, AGV, and pallet conveyor lines."

* In addition to this, we can handle a variety of other forms such as receiving from AMR, AGV, and pallet conveyor lines."