Case Studies

Useful Worksite Knowledge

Points to note when using powder handling equipment during seasonal changes

If powdered raw materials melt or solidify inside containers due to seasonal temperature and humidity changes, there is a high risk of disruption to the entire process. Here are some points to keep in mind as the seasons change.

⚫︎Adjustment of air conditioning equipment

- Adjust the direction so that air conditioner airflow does not directly hit the equipment.

- Install circulators to circulate the air inside the factory.

- Install circulators to circulate the air inside the factory.

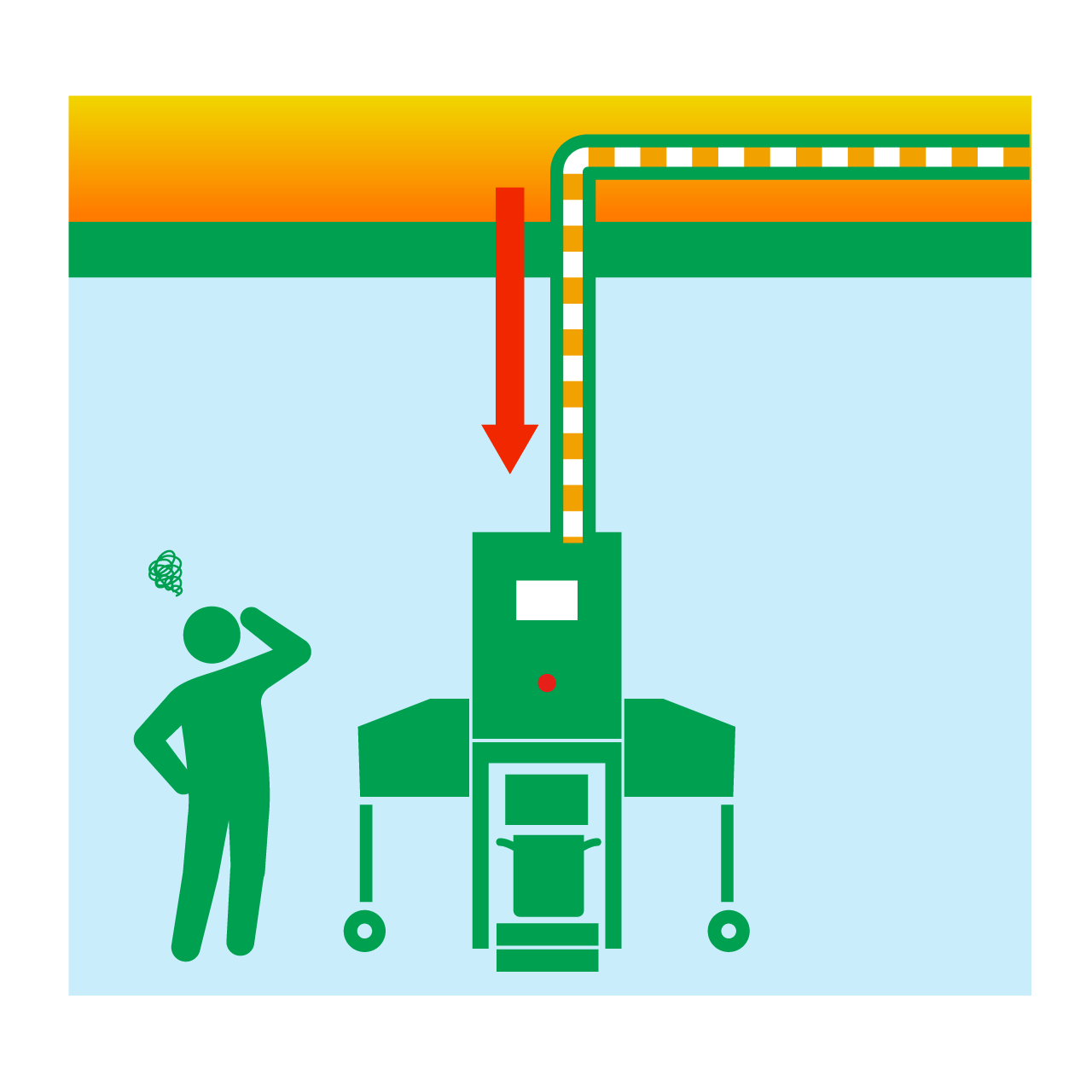

⚫︎Measures to prevent condensation on control panels and conduits

During indoor air conditioning, consider the piping layout to prevent warm air from the ceiling space from entering through conduits into the control panel.

⚫︎Consider shifting from an outdoor silo to an indoor silo

In a region with large seasonal temperature fluctuations, or where an outdoor silo is exposed to direct sunlight, switching to an indoor silo that allows easier temperature and humidity control of raw materials is also effective.

▲PowSilo Fabric Model

⚫︎Consider introducing a lump breaker or coarse crusher

As a countermeasure against consolidation of sugar, salts, and similar materials stored under high-temperature and high-humidity conditions, it is also possible to retrofit a lump breaker “PowCrusher” that coarsely crushes the raw material, or a “Pow Breaker” that automatically performs coarse crushing inside a paper bag before bag opening.

▲PowCrusher ▲Pow Breaker

⚫︎Air conditioning management using a dehumidifier

During high-humidity periods from spring through the rainy season to summer, installing a dehumidifier in the factory helps maintain a stable air environment.

⚫︎Antistatic and electrostatic countermeasures

During the dry season from autumn to winter, consider taking measures to prevent static electricity (such as by earthing) within the factory to prevent impacts on equipment and ensure work safety.