Case Studies

Useful Worksite Knowledge

Daily Inspection of a Sifter

LINESIFTER and PowSifter are pieces of equipment that particularly require maintenance

For sifting and removing foreign-material from powder materials, the "LINESIFTER" for pneumatic conveyance lines and the "PowSifter" for chute conveyance lines are typical pieces of equipment used. Since both sifters have a beater blade that rotates at a high speed inside the cylindrical sieve, regular maintenance is essential. In this page, we will introduce some inspection points that you can easily do by yourself to prevent problems occurring (and which are often overlooked).

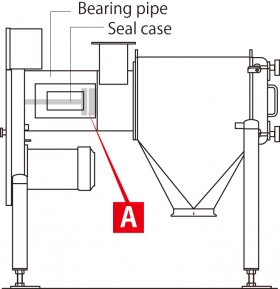

Be careful about sealant shaving discharge

In the bearing pipe of the LINESIFTER or PowSifter, black shavings may be discharged under the seal case (A). These are shavings (wear) from the sealant caused by the rotation of the shaft. In order to prevent shavings from entering the bearing, TSUKASA has adopted a system to discharge the shavings into this location.

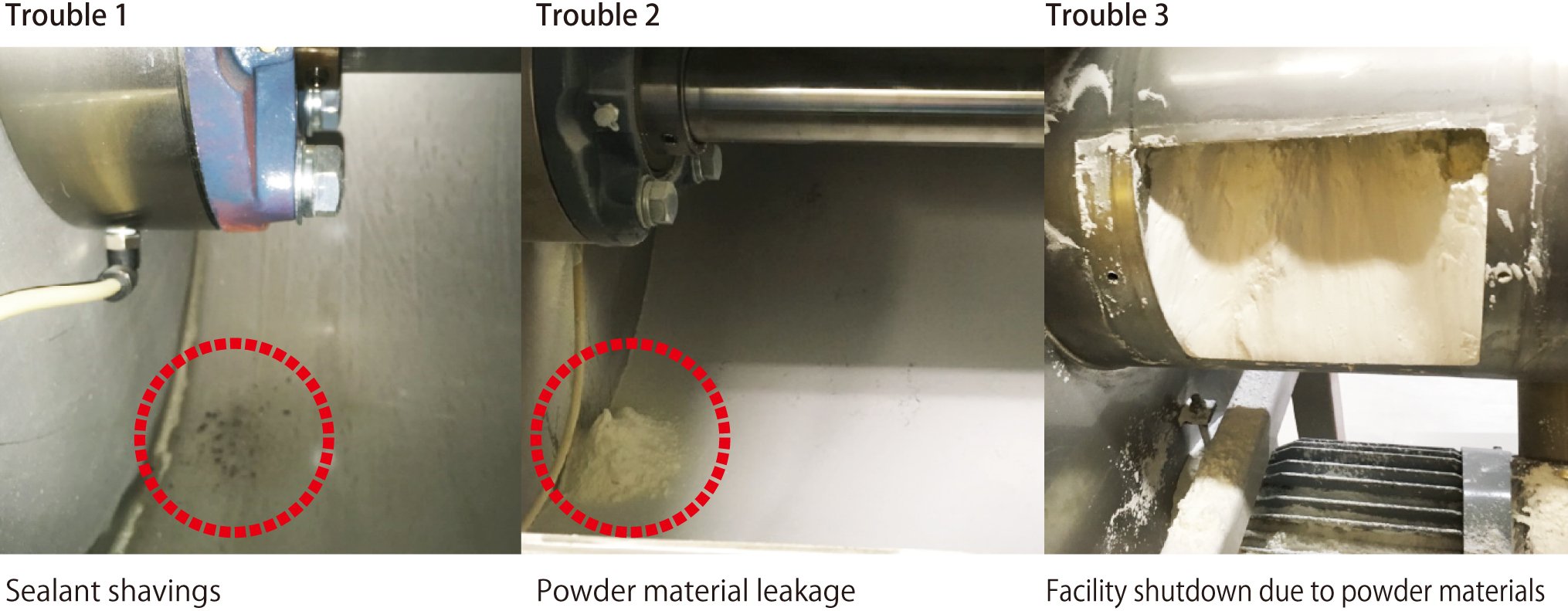

If left as is, powder materials can leak out

The occurrence of shavings indicates a sign of a powder leakage. If left as is, the powder materials will eventually leak out, causing serious problems such as powder spewing and facility shutdown.

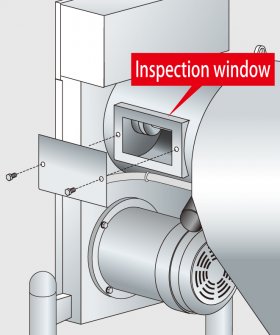

Easy check by looking through an inspection window

We recommend that you carry out your own daily inspections. The method is very simple: Just look inside through an inspection window next to the bearing pipe. If you find any black shavings, it is time to replace the sealant, so please contact us.