Case Studies

Useful Worksite Knowledge

What should be checked when the “measured weight does not match the set value”?

In the weighing process, the measured weight does not match the set value (too heavy or too light), so is there something wrong with the weighing equipment?

⚫︎Check for load cell interference

Open the cover and check for material adhesion or contamination on the load cell.

For the Divider Scale Hybrid ▶︎▶︎▶︎▶︎▶︎

For the Divider Scale Hybrid ▶︎▶︎▶︎▶︎▶︎

Check the load cell inside the cover circled in red

⚫︎Check for any remaining raw material inside the hopper

If residual raw material or adhesion is found inside a hopper-type weighing equipment, increasing the number of times the knocker strikes is one possible countermeasure. A knocker can also be retrofitted to the existing equipment. For a new installation, surface treatment to “prevent material adhesion” can be applied to the inside of the hopper.

Knocker

⚫︎Residual powder around the discharge outlet flap gate

Each time the flap gate at the raw material discharge outlet closes, nearby is residual powder mixed in? In addition to frequent cleaning, applying surface treatment around the discharge outlet can prevent material adhesion.

Applying surface treatment around the discharge outlet as a countermeasure

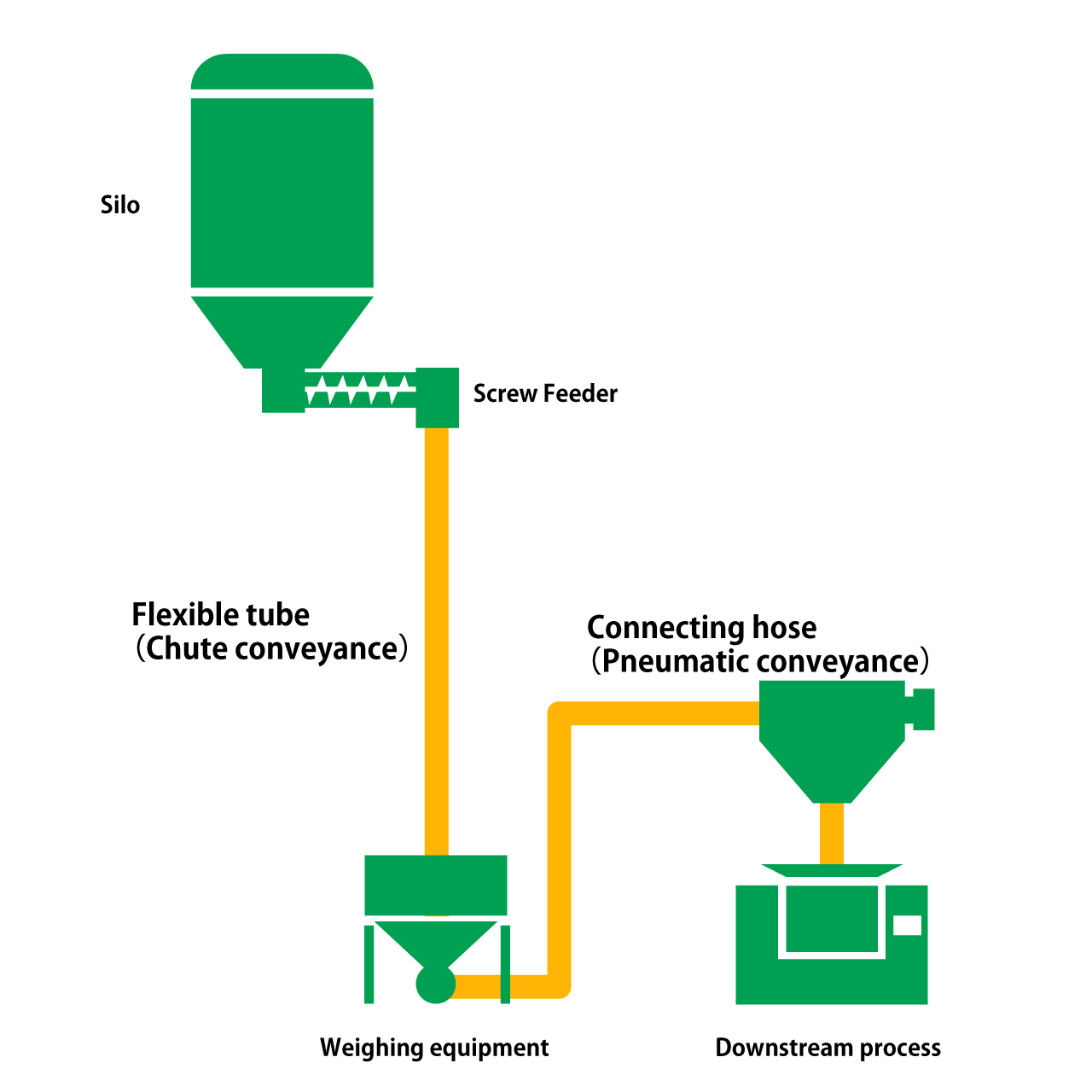

⚫︎Is the tension of the tube or hose constant?

If the tension of the flexible tube (for chute conveyance) connecting the silo and the hopper-type weighing equipment, or the connecting hose (for pneumatic conveyance) linking it to the downstream process changes, it will affect the measured weight value. After disassembly and reassembly during cleaning, performing a weight test in addition to an operator check is recommended.

⚫︎Is anyone in contact with the weighing equipment?

Even slight contact—such as an operator accidentally “pushing the weighing equipment,” “leaning a vacuum cleaner against it,” or “catching piping on it”—can affect the measured weight value. Consider installing a cover or protective guard for the weighing equipment.

⚫︎Pay attention to changes in the air conditioning environment

In particular, when minute and high-precision weighing is required, pay attention to the air conditioning around the weighing equipment, the direction and strength of fans in the factory, and the inflow of outside air when doors are open.

⚫︎Check whether the dust collector is clogged.

If the dust collector filter is clogged with raw materials, accurate weighing cannot be expected. Be sure to check and clean it regularly.

⚫︎What about changes in the physical properties of the raw materials themselves?

When the temperature, humidity, and moisture content of raw materials change depending on the season, or when using new raw materials that have never been handled before, it is necessary to check “whether weighing is being performed correctly.”