Case Studies

Useful Worksite Knowledge

Two weighing methods (from silo to the next process)

How are the powder raw materials stored in the silo weighed and sent to the next process? We will introduce two weighing methods that are often actually used on customers' production lines.

Two methods for weighing and sending raw materials from the silo to the next process

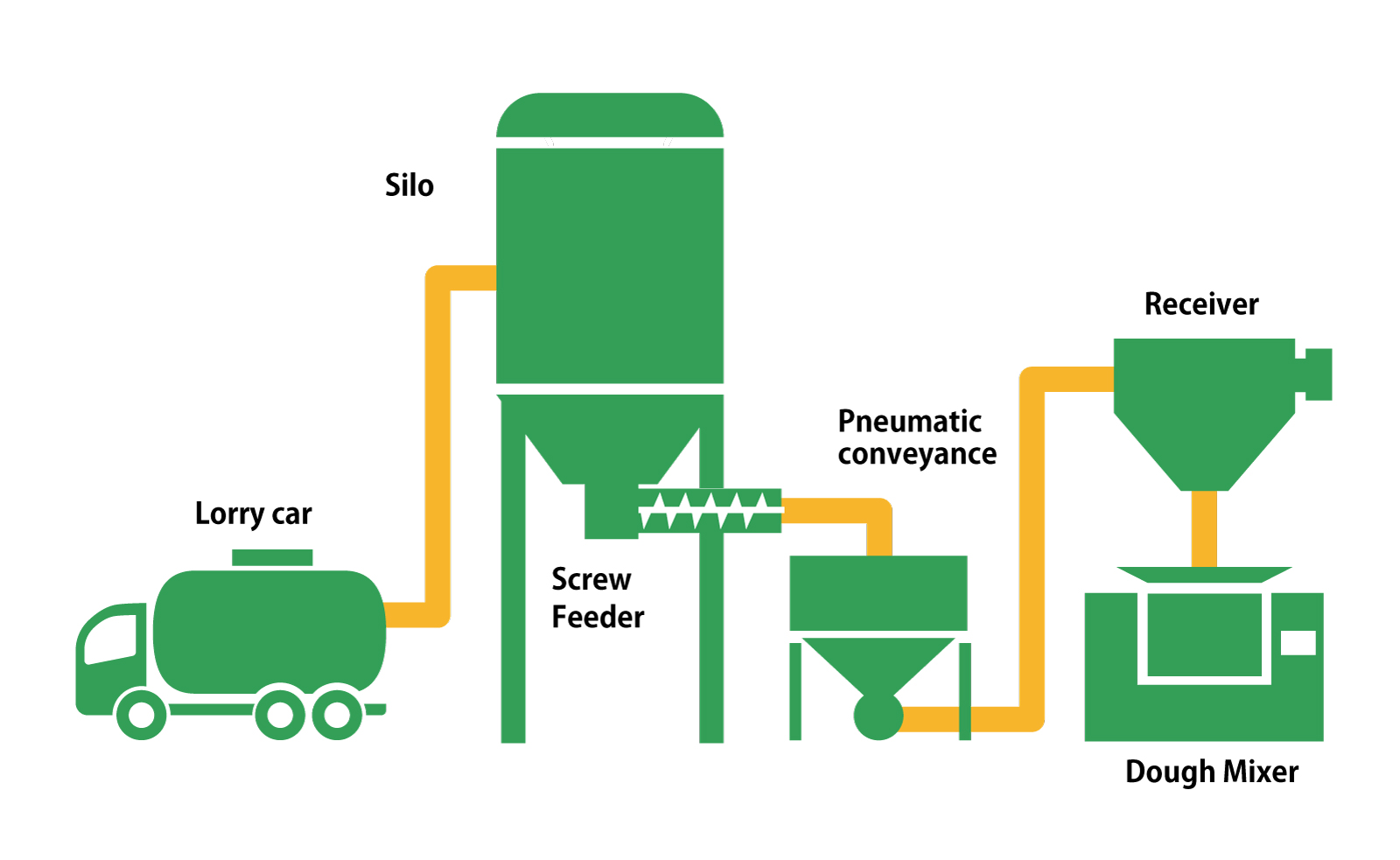

Also quickly supplies to multiple mixers

Self-weight falling weight

In large factories, raw materials are often dumped from a lorry car into a silo, where they are automatically weighed using weighing equipment (PowScale) installed at the bottom of the silo. Since this allows for speedy weighing, it is also recommended for situations where a large number of different materials need to be weighed in one batch, such as when feeding multiple dough mixers in a bread factory.

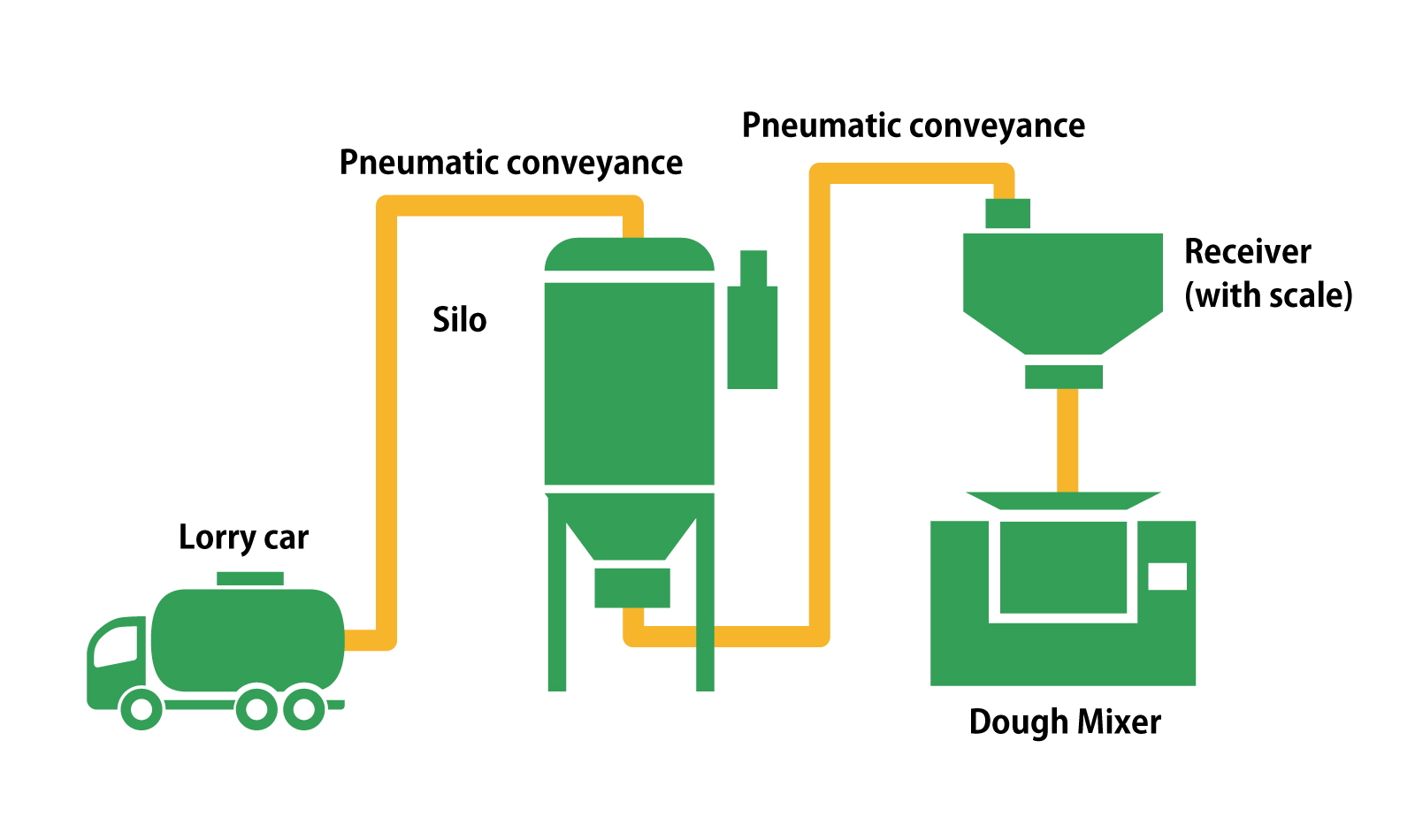

Space saving and reduced implementation costs

Vacuum weighing

Install a receiver (with weighing equipment) on top of the dough mixer. As the raw materials are discharged from the silo, they are weighed at the destination. Since there is no need to install weighing equipment (PowScale) below the silo, the total amount of equipment is reduced, which saves space and reduces implementation costs.