Characteristics of powder: Conveyance

Other

Various characteristics of powder

Each individual grain of a powder has various characteristics depending on the size of the grain (grain size), shape, weight (bulk specific gravity), fluidity and included water content. Methods and routes for conveying powder in food plants, etc. need to be designed carefully according to characteristics of the raw material powder.

Academically difficult topics such as powder technology and fluid-dynamics will arise if we focus thoroughly on the characteristics of powder. However, in this article, let us explain about powder related to food products, which is often used and familiar to everyone.

Main characteristics of powder used in food and etc.

| Kinds of powder | Characteristics of conveyance, etc. |

|---|---|

| Flour (strong flour) | Large grains, and easy to slide. |

| Flour (weak flour) | Small grains, and hard to slide. |

| Rice flour | Ease of handling varies depending on the size of the powder. |

| Buckwheat flour | Small grains, and hard to handle. |

| Starch | Small grains, and hard to handle. |

| Sugar and salt | Hard grains, and vulnerable to heat and humidity. |

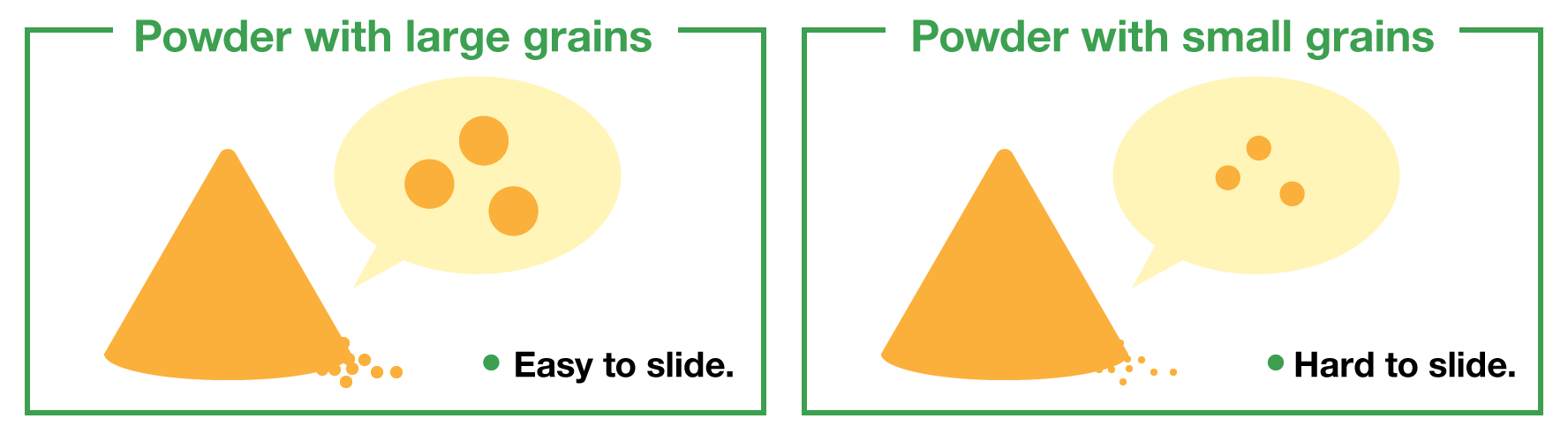

Characteristics depend on the size of the powder grains.

Powders with large grains tend to be easier to convey, while those with small grains tend to be characteristic of easily getting moist, hard to slide, and enable static electricity to easily occur, making it difficult to convey.

In addition, sugar is vulnerable to heat—if it dries, it will clump together, while salt clumps together by humidity. Therefore, it is necessary to care about the temperature, humidity, and environmental conditions. In the case of powders such as sugar and salt which have hard and large grains, they can easily cause damage, etc. to machines during conveyance, so frequent machine maintenance is required.

As mentioned, powder has various characteristics. Therefore, when considering methods and routes for conveyance at food plants, etc., it is necessary to carefully consider the design, including the size and shape of the tank after determining the characteristics of the handled powder, and changing the angle of the hopper.

At TSUKASA , we propose optimal powder conveyance methods considering the environment and kinds of powder the customer handles, based on our accumulated experience and know-how and professional knowledge in powder.