Reduce Your Workload With Automation [Transporting Powder to the Place of Use]

There is a significant conveyance distance for a bag of raw powder material to be received at a warehouse on site, and for it to be delivered to the location where a processing machine is actually used. This is another big point of automation.

Heavy labor = the work of carrying powder bags by hand

Reducing "carrying something to do something"

Since powders are used in processing machines in plants, it is necessary to review manual labor where workers simply carry the powder. If you can focus on working on doing something instead of having to carry something to start work, you can expect to increase the productivity of the entire plant.

Also prevents foreign matter and dust scattering

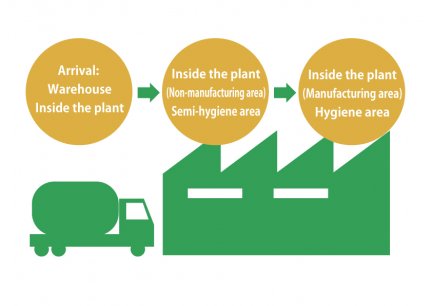

From the acceptance of powder bags to using the contents, the cleanliness will increase in the order from the "polluted area", "semi-hygiene area", to the "hygiene area". Therefore, during transportation, it is important to keep the material as closed as possible and to keep it out of contact with the outside.

Overall image of the automated powder conveyance system (pneumatic conveyance)

Automatic conveyance in a "Cannot be insanitary” and "will not cause any pollution" state by adopting an in-line system.

Dumping Server

There is no need for a stage (cradle) for cutting into powder bags, and the burden of feeding powder by hand can be reduced.

TSUKASA considers there are three points of success in automation

Understanding the benefits of automation

When considering automation, it is important to understand specifically what advantages and disadvantages your company has, such as “improving retention rate and securing human resources,” “improving production efficiency at plants,” and “cost effects over the medium to long term.”

Consensus building on site

It is natural that there is a sense of resistance to changing the process that you are used to. Hold an in-house briefing session and build awareness regarding "what is the purpose of automation?" with everyone.

The ability to execute plans, which includes administration

Instead of having the attitude of "let's automate things because there are no people", take on the stance of "let’s improve the worksite environment with automation!" If you work with a positive attitude, you will be able to see the next improvement measures from there.

Please feel free to contact Tsukasa Kogyo for a consultation on current problems your facing and for the introduction flow of automation!