Reduced Processing Costs by Crushing Waste Products into Particles

Crushing and Millng Process

| Type of industry | Confectionery and bread companies |

|---|---|

| Introduced products | PowCutter |

Background and problem

We would like to improve in-factory logistics and reduce processing costs for waste products that are produced from sweets and bread

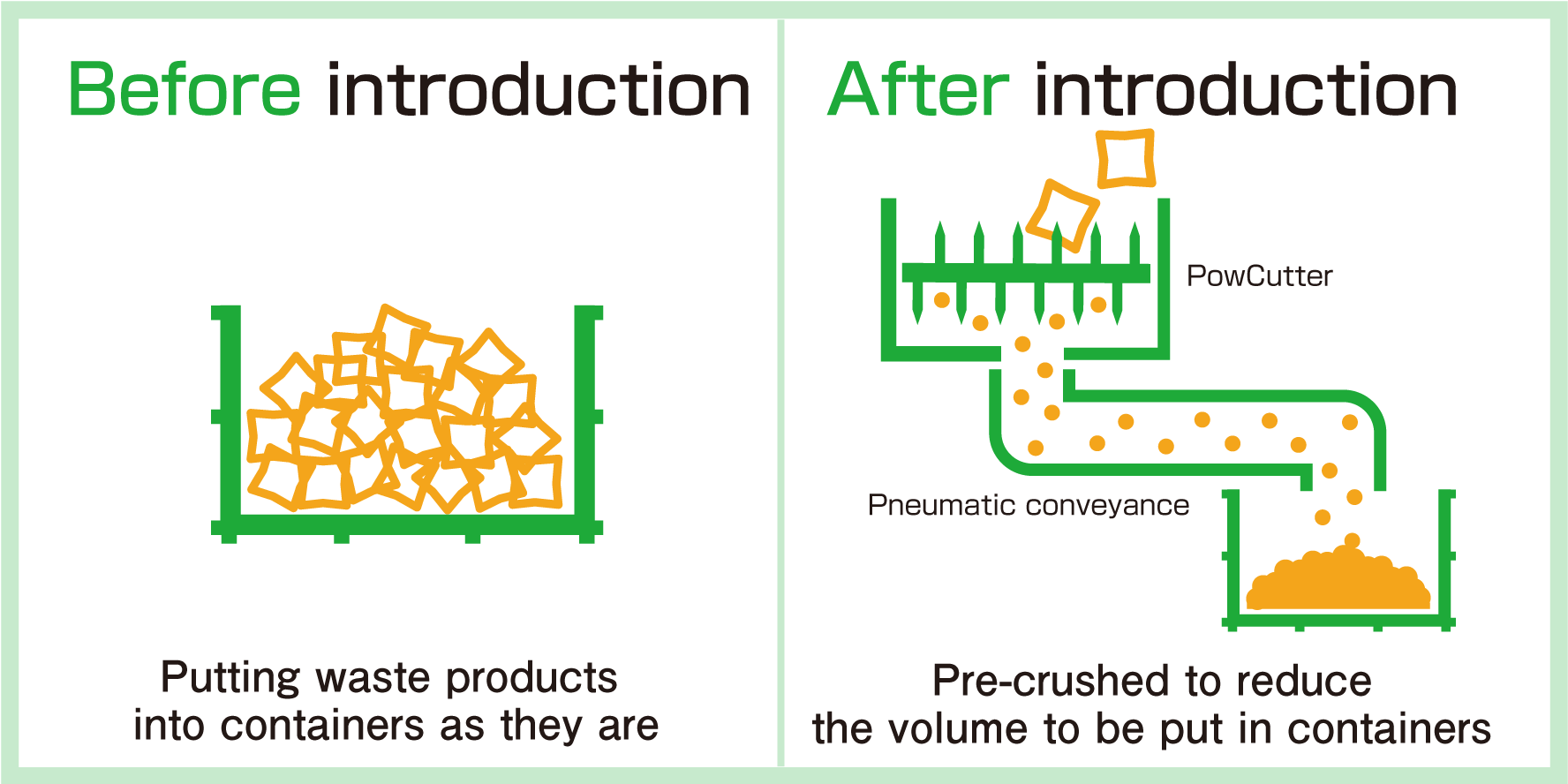

On a confectionery and bread production line, waste products that were not up to product standards used to be conveyed by cart to the waste products warehouse and then put in containers.

We were contacted by a customer stating: ""We would like to reduce our volume of waste products, and want to fully pack them into containers."" This was because the cost of outsourcing to a disposal company is determined by the number of containers.

Suggestions from Tsukasa

The PowCutter helps reduce the volume of waste products by means of crushing

We made the suggestion of "crushing the waste products into powder using the PowCutter (crushing machine), and then packing it into containers." This method significantly compressed the volume of the "waste product's original form" and dramatically increased the amount that could be packed into a single container. The powder also made pneumatic conveyance possible, and there was no more tedious work when transporting it. The process flow involves "sorting waste products" → "putting them into a PowCutter and crushing them into powder" → "pneumatically conveying the powder and putting it into a container."

>> See details of the product

Why TSUKASA was chosen

Extensive experience in terms of smooth coordination between crushing and pneumatic conveyance

The TSUKASA's PowCutter was originally developed for the production of bread crumbs, but has also been used in crushing of a variety of products. Moreover, the smooth coordination of PowCutter and the pneumatic conveyance system was highly evaluated, especially thanks to our extensive years of experience as a "comprehensive powder engineering company."

Results of introduction

Reduction of waste product handling costs

By turning waste products into powder, a greater volume of waste could be packed into containers which significantly reduced disposal costs.

Reducing transportation work concerning waste products

Through pneumatic conveyance of waste products, it was possible to eliminate the work of transporting waste products to the waste products warehouse.

Securing work-site safety

To ensure safety if an unlikely event occurs, safety devices have been carefully laid out around the PowCutter, which is a special cutter rotating at a high speed.

Even more applications

Can be applied to a wide variety of food processing applications

TSUKASA's PowCutter can be used to crush not only bread, but also a wide variety of other raw materials, including biscuits, pie dough, cacao mass, rice, seaweed, and waste dried noodles.