Disassembling and cleaning the sifter is now possible even for new employees

Material Receiving and Powder Feeding Process

| Type of industry | Food manufacturer |

|---|---|

| Introduced products | LINESIFTER (Removable bolt) |

Background and problem

Water-washing is simple to do once, but the burden increases if done frequently

"Since we use different types of powder raw materials in the same line, we need to wash the equipment with water every day. Can you help to alleviate some of the workload?"—this is a request we have received from customers who have introduced a sifter into their workplace.

↓

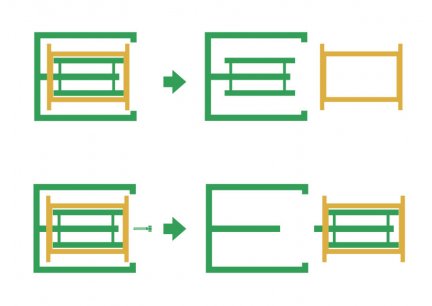

In the standard LINESIFTER, the rotating beater and shaft are integrated into the pulley (belt drive). Since the beater can only be removed using special tools, it can be difficult to clean it thoroughly during water-washing due to its complex shape.

↓

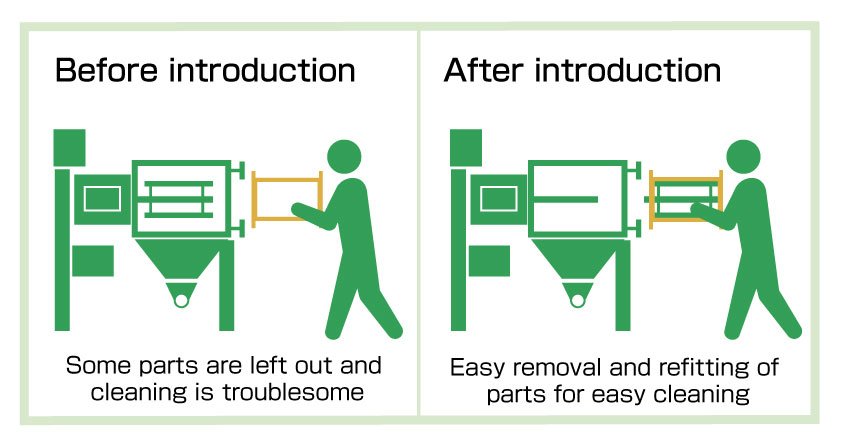

In sites where frequent water-washing is performed, removing and refitting the beater reduces the burden of cleaning. In addition, one customer said, "if it could be easily removed and refitted even by new employees, it would be a great help in many ways."

TSUKASA’s response

The beater can be removed by removing one bolt

A new design was adopted where just the beater can be pulled out by opening the inspection door and removing one center bolt. By leaving the shaft inside the body, there is no need to remove the pulley, and no special skills are required for assembly because the drive part is not disassembled. The only skill required is loosening and tightening the bolts.

Results of introduction

Even new employees can carry out water-washing by themselves

Even new employees and inexperienced staff can now easily remove, wash, and assemble the beater.

Easy cleaning of the inside of the main unit

After removing the beater, you can easily access the inside of the body where the shaft remains, and carefully clean every detail.

Easy to clean the sieve

With the LINESIFTER, you can easily clean the cylindrical-sieve (net) inside the body by opening the inspection door and pulling out only the sieve. No special skills or tools are required. It is also possible to replace the net in a short amount of time.

↓↓↓↓↓

Smooth transition to production of the next lot

Even when skilled staff are not on site, preparations for the next lot production can be made smoothly, and there is more room for staff rotation.

TSUKASA's basic stance

Endeavor to make proposals tailored to the customer's production situation

In the production of small lots of various products, it is very important to create a system that can handle multiple raw materials on the same line in terms of effective utilization of people and space. At TSUKASA, we carefully listen to customers from the design stage of a line, and make proposals such as: "If you clean your equipment frequently, we recommend a model that is the most straightforward to clean, even with initial cost."