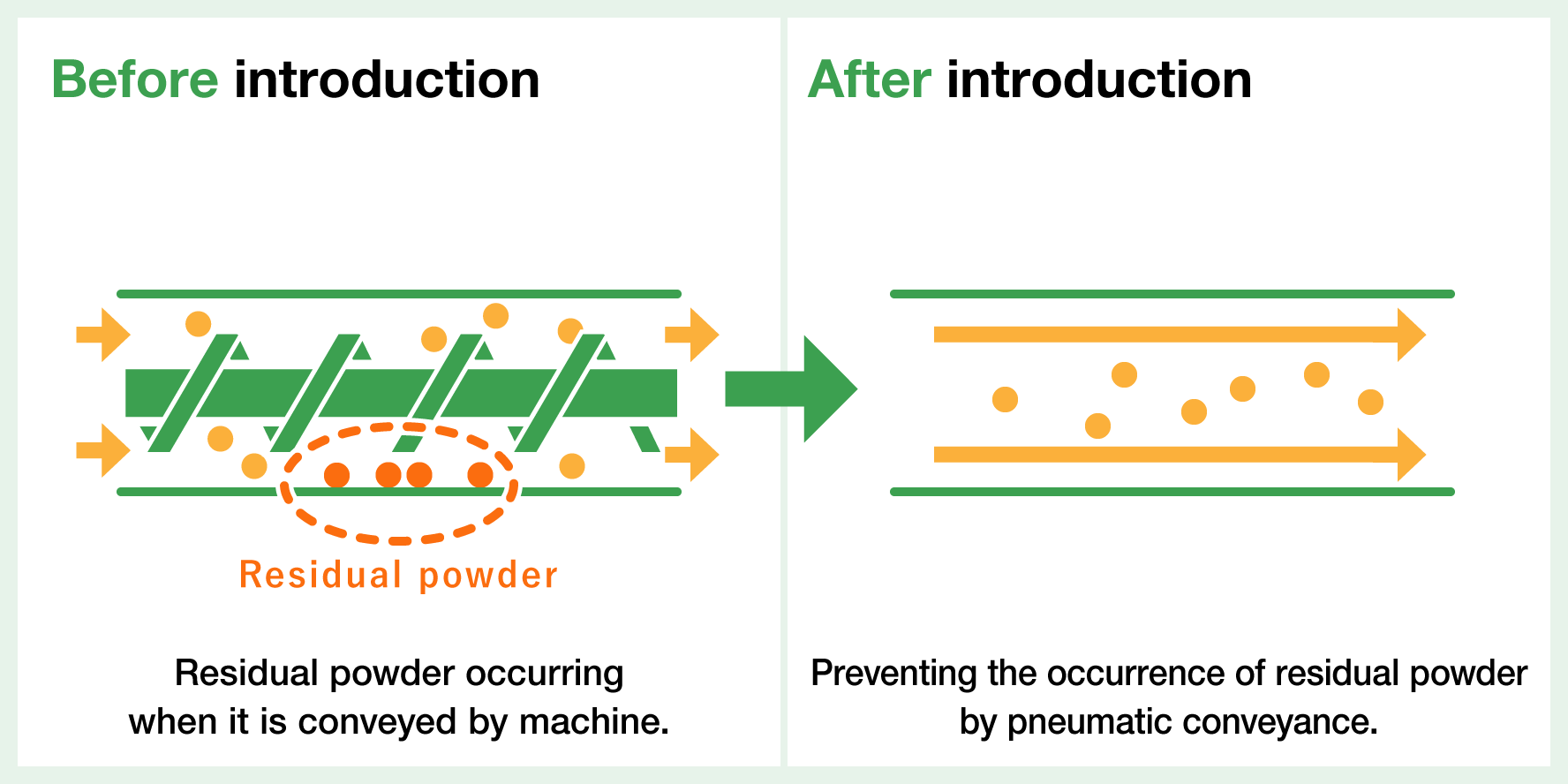

Solving the problem of residual powder during conveyance.

Handling Process

| Type of industry | Flour milling company |

|---|---|

| Introduced products | Rotary Valve, PowFilter |

Background and problem

We would like to reduce the amount of residual powder and achieve a space-saving environment.

We were contacted by a flour milling company which conducted mechanical conveyance in the process of manufacturing raw material powder. They were troubled by the residual powder that gathered in their machines, no matter what they did.

Since mechanical conveyance takes up a large amount of space for installation, they wanted to reduce the residual powder as much as possible and realize a space-saving environment.

Results of introduction

Constant supply equipment Rotary Valve

We proposed changing the conveyance method by using pneumatic conveyance which uses aerodynamic force, rather than mechanical conveyance. For performing pneumatic conveyance, the flour milling company introduced a Rotary Valve in order to send stored powder to the next process in a fixed quantity.

>> See details of the product

Dust collector PowFilter used as a receiver from pneumatic conveyance.

They introduced not only a Rotary Valve, but also a PowFilter used as a receiver from pneumatic conveyance. The PowFilter comes with a large inspection door making for easy maintenance on this dust filter, including inspecting and cleaning the inside.

>> See details of the product

Realizing a reduction in residual powder by pneumatic conveyance

Compared to mechanical conveyance (screw conveyors, chain conveyors, and bucket conveyors), there is only a small amount of residual powder that occurs with pneumatic conveyance, and it can be installed while saving space. In addition, risks such as malfunctions decreased compared to mechanical conveyance, which led to a reduction in maintenance costs.

We proposed pneumatic conveyance in this case, however, the appropriate conveyance method will vary depending on the characteristics of the raw materials and plant.

TSUKASA provides optimal proposals tailored to the respective characteristics of pneumatic conveyance and mechanical conveyance according to the powder being handled, and the plant.

Features of pneumatic conveyance

- Advantages: Little residual powder. Able to be installed while saving space.

- Disadvantages: Difficult to convey materials for long distances.

Features of mechanical conveyance

- Advantages: Able to convey materials for long distances.

- Disadvantages: A large amount of residual powder occurs compared to pneumatic conveyance. There are numerous machinery parts, so a large installation space is required. Frequent maintenance is necessary.