Spout Piping - Self-Weight Falling and Pipe Angles -

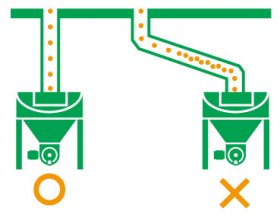

EquipmentIn "Spout piping", which runs through the floor of the plant and sends powder from the upper floor to the lower floor, self-weight falling through the chute is the basic way of transportation. Here, it is important to focus on the "angle of the pipe" in the layout, so that the powder flows smoothly by gravity.

Efficient spout piping

There are four points:

Point 1

Design pipes that cannot be angled first

There is no problem if the machine to receive the powder was on the lower floor directly below the machine to send the powder on the upper floor. However, if the two machines have a distance between them, the angle of the pipe will be reduced and the efficiency of the self-weight falling will also be reduced. If you prioritize the design of such piping and ensure sufficient angles, and then decide on other pipe routes accordingly, you can achieve a high-efficiency overall layout.

Point 2

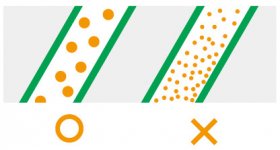

The finer the powder, the more secure the angle setting

In general, powder of a larger grain size falls easily due to its own weight, and powder of a smaller grain size has more air resistance, resulting in slower falling. This is the same in spout piping, too. Powder of a small grain size and with less fluidity needs a sufficient angle of the piping.

Point 3

Organize various piping routes

There are many pipes in a plant, including electrical systems. To avoid the situation of "various pipes being tangled together", consider the arrangement of routes for powder-related pipes and other pipes. It not only helps the plant in terms of aesthetics, but also helps you to make maintenance easier to carry out and avoid trouble from occurring.

Point 4

Explore a wide range of additional features

The piping parts of TSUKASA have an extensive lineup, including the "Inspection Spout with Sensor" that automatically detects clogging in piping, "Inspection Spout" that enables you to see how the powder is being transported, "Cushion Spout" that reduces the speed of the powder falling from a height, "Speed Band" that can be installed and removed in a single operation without the need for tools, and "Twin Miter Bend" which can be tilted freely from 0° to 45° . Please consider these products according to the environment of your production site.

>> See details of the product.