Tips for Cleaning and Maintenance

EquipmentTake pictures before starting disassembly

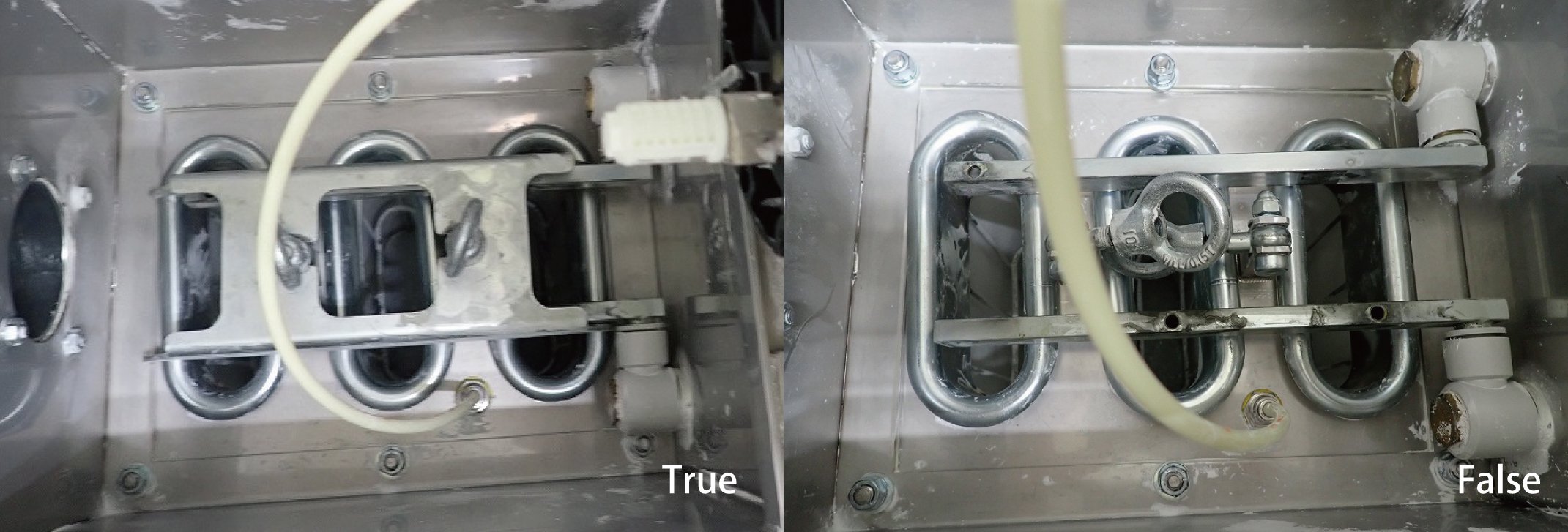

Before disassembling the equipment for cleaning or maintenance, take pictures of the filter, valve, bolt areas, and "assembly parts" and "connections.” Those pictures help to prevent the misassembly of parts after cleaning, to compare the condition before and after maintenance, and to compare the deterioration level of consumable parts. If you take pictures of the entire piece of equipment, not just partial close-ups, you can clearly see "which picture shows which part.” In addition, you can also save the photo data for future reference in case of maintenance or trouble.

▲ Picture: The injection nozzle can be assembled incorrectly, leading to problems.

Be careful not to injure yourself with stuck powders

When removing the inspection port or side plates of the equipment, powder materials may be stuck on the inside of the flange, growing into sharp-edged shapes (e.g. granulated sugar). Carelessly inserting your hand may result in getting an unexpected injury. Use a scraper, etc. to carefully remove the stuck powder before carrying out any work. In addition, note that rubber plate packing that has hardened due to aged deterioration can also cause injury.

Holding a "safety workshop" for customers

When carrying out installation and maintenance of equipment, TSUKASA also holds a "safety workshop" and "maintenance workshop" for customers. Participate in these workshops and use the information gained to ensure safe and secure use of your equipment.