Change in specifications to a switching valve that can be used in the secondary battery manufacturing equipment

Valves and Piping Parts

| Type of industry | Chemical engineering company |

|---|---|

| Introduced products | Two-way Valves (PowChange Simple Secondary battery manufacturing equipment-compatible) |

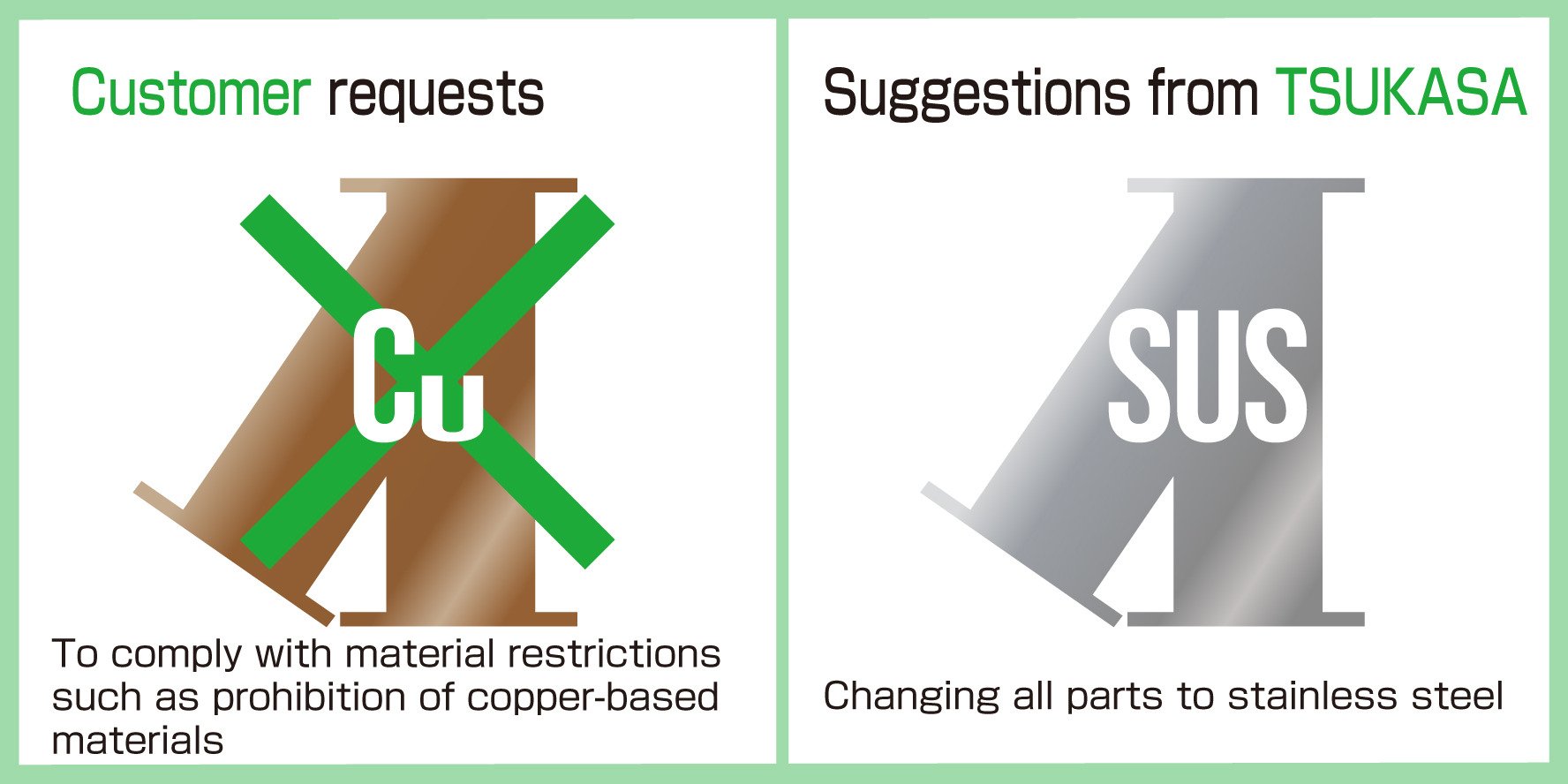

Customer requests

Materials required for secondary battery manufacturing equipment

The secondary battery manufacturing equipment has certain conditions for materials that can be used in the equipment, such as "no copper-based materials" or "no electric nickel plating". The customer asked us if we could make a two-way valve conforming to those conditions, while maintaining the function to transport powder material via the chute as per the settings.

Suggestions from TSUKASA

Examining changes to specifications based on CE-compliant products

Based on the "PowChange Simple CE-Compliant (EU standard)" that was already developed earlier, we started to examine the specification changes.

↓

We received information from the customer on the physical properties of the powder they handle (grain size, ionization, flooding, abrasion, etc.), and explored the materials and structures of the parts that are appropriate for this.

↓

Maintaining close contact with our customers, we checked materials and structures, and made prototypes. In addition, we selected products appropriate for the secondary battery manufacturing equipment such as cylinders, and also ordered a structural diagram as necessary to facilitate the examination.

↓

A confidentiality agreement was made with the customer since the beginning of the development, so we were able to proceed with the production under solid information management. We successfully delivered and incorporated the product into the equipment.

Main points of the specification change

Changed all parts to stainless-steel while maintaining performance

All parts except the sealing material (including fastening components such as bolts) were changed to stainless steel, while meeting the performance requirements. By not using copper-based or other highly ionizable materials, we have developed a special-specification switching valve that contributes to preventing the occurrence of defective products.

In addition, the main point of the CE-compliant product that was developed earlier was that a safety cover (dustproof structure) that completely covers the drive part of the cylinder could be installed, and a CE-certified magnet valve and sensor switch could be incorporated inside it.

TSUKASA's stance on special specifications

We also flexibly respond to chemical-related needs.

In addition to this case involving secondary battery manufacturing equipment, TSUKASA has received many inquiries from chemical engineering companies. By sharing with customers "what kind of powder devices they are looking for" and the physical properties of the powders they handle, we will work together to consider "what materials and structures are appropriate" and aim to develop products under solid information management.