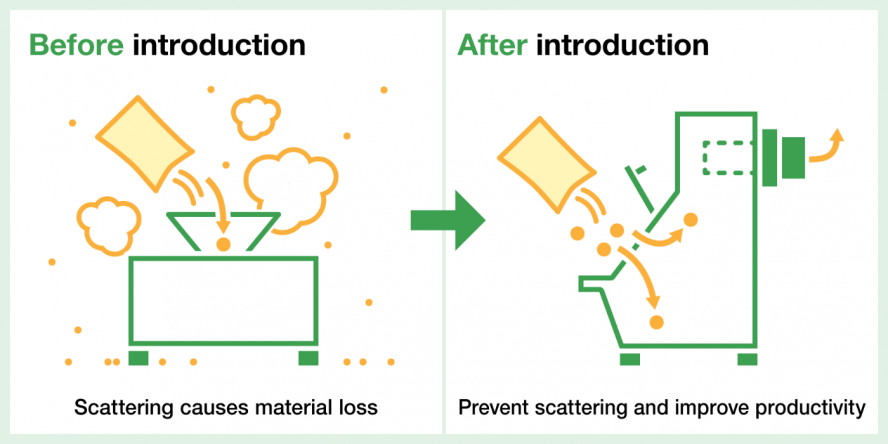

Stop powder from scattering and improve on material losses

Dust Collecting Process

| Type of industry | Food (confectionery) manufacturer |

|---|---|

| Introduced products | Dumping Server |

Background and problem

We would like to reduce dust when feeding in powder materials

A confectionery manufacturer was troubled by the large amount of powder scattering that occurred when feeding in powder materials. Scattered powder takes time for cleaning, etc., and workers have to work in an environment where powders were swirling around, which was considered a sanitary problem.

Results of introduction

Hygienic Dumping Server with built-in dust collector

You could prevent scattering by putting a hood at a feeding port and collecting dust with a duct, etc., but an add-on hood may not efficiently collect dust depending on the shape, and the collected dust will be stored in a collection bucket of the dust collector as waste.

As a result, they chose the Material Feeder Dumping Server with built-in dust collector.

>> See details of the product.

Prevent material scattering and improve productivity

We installed our damping server that reduces dust scattering during in-feed with the built-in dust collector, and succeeded in reducing scattering when the material is fed in. It recovered collected powder as they are in the equipment and reduced material loss, solving their problems.